Some people have asked me for the files of PHOSPHOR's predecessor, the ARCHER. The video circuit of this project is exactly the same. If you don't need the MIDI functionality, you can omit the vactrols and everything below to basically get the ARCHER. Another possibility would be getting the AVE MOD by syntonie.fr, of which the ARCHER was more or less cloned.

In reverse, if you don't want manual controls, you can omit the potentiometers and toggle switches. I would recommend keeping those for calibrations though.

I used both the ARCHER and PHOSPHOR prototypes with PAL analog video hardware and was very happy with the results. It should work with NTSC as well, but couldn't try it myself.

If I find the time, I will upload a version with the SOP version of the IC, since the DIP version is out of production (but can still be sourced relatively well).

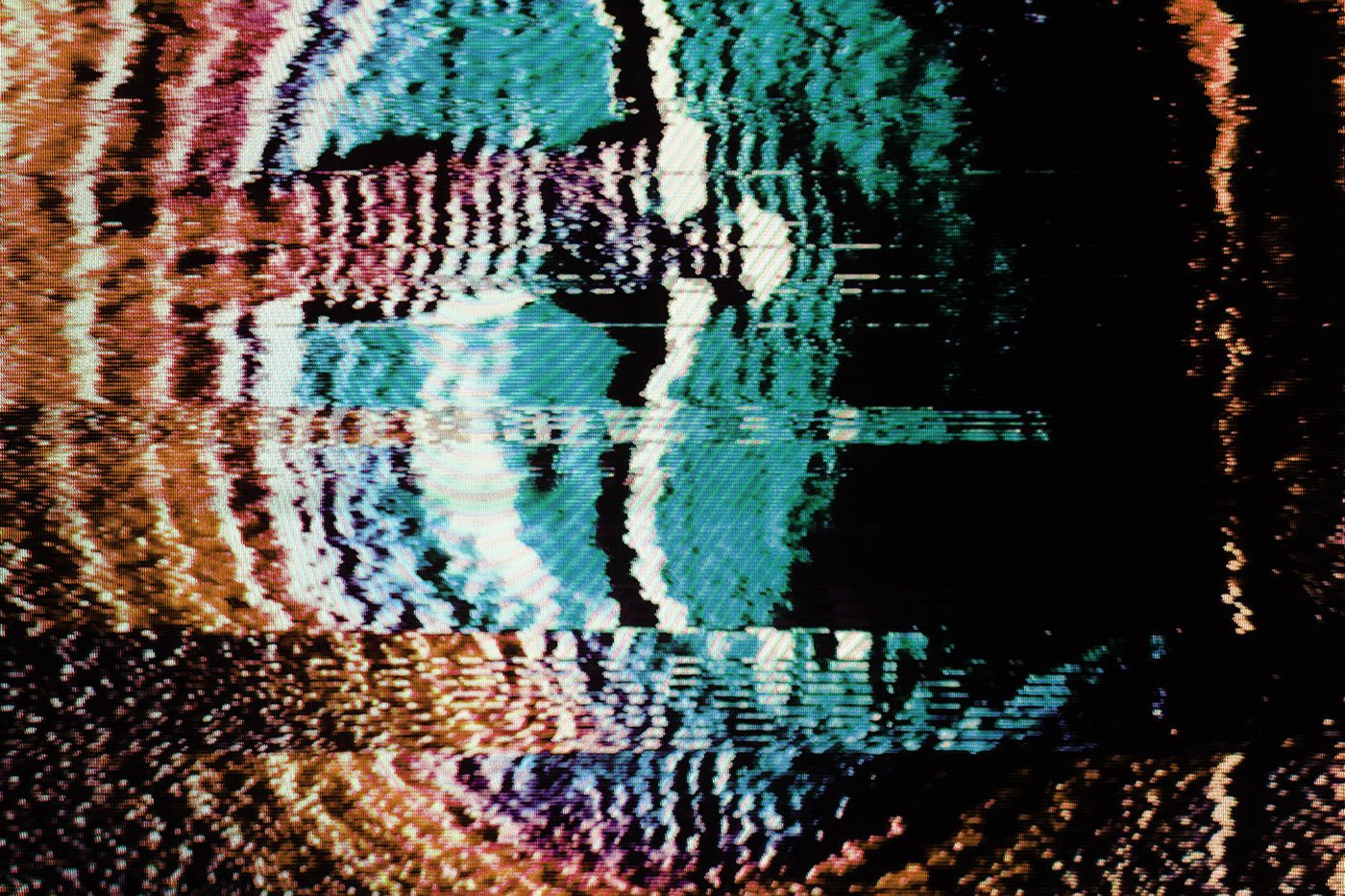

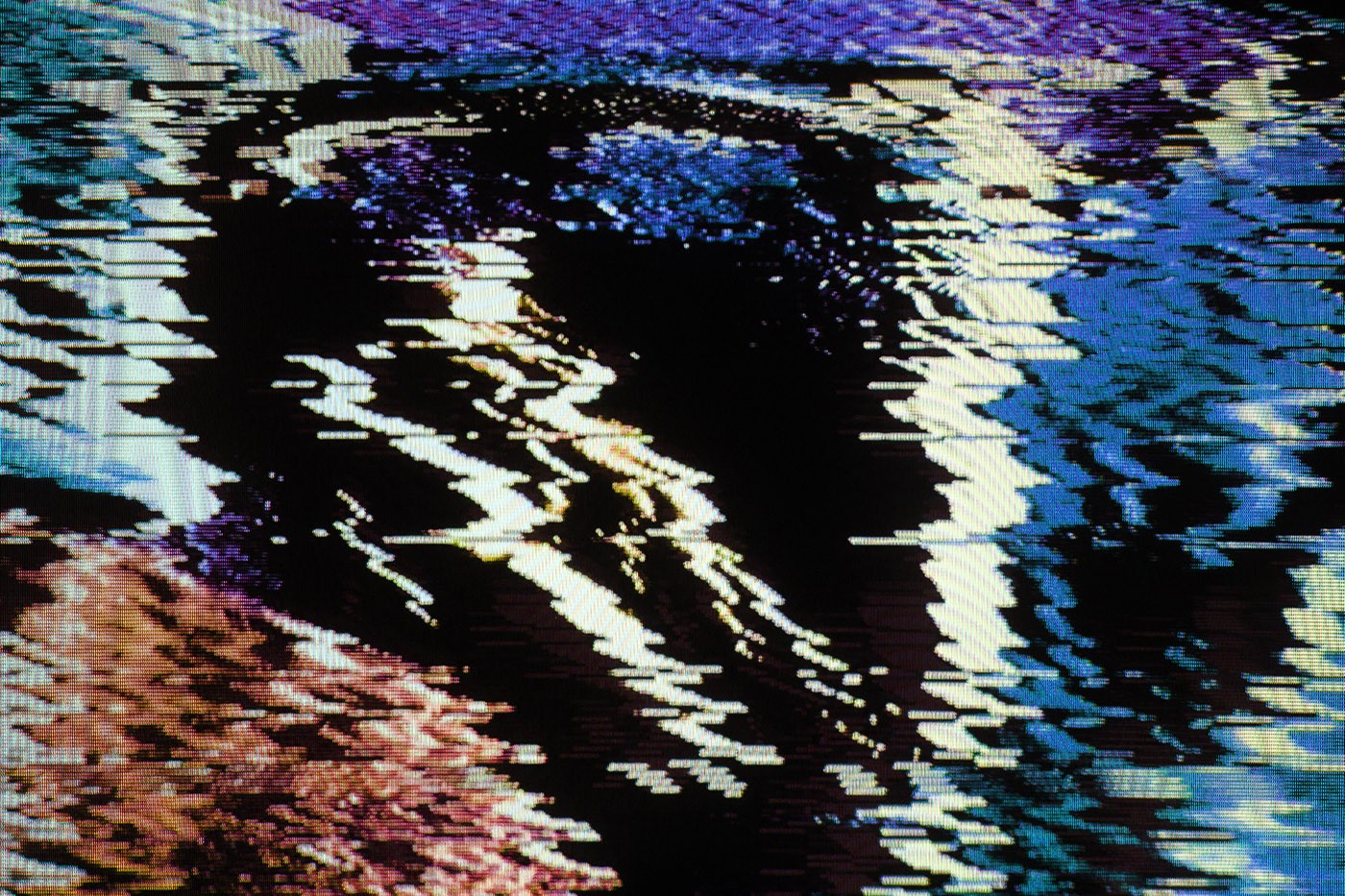

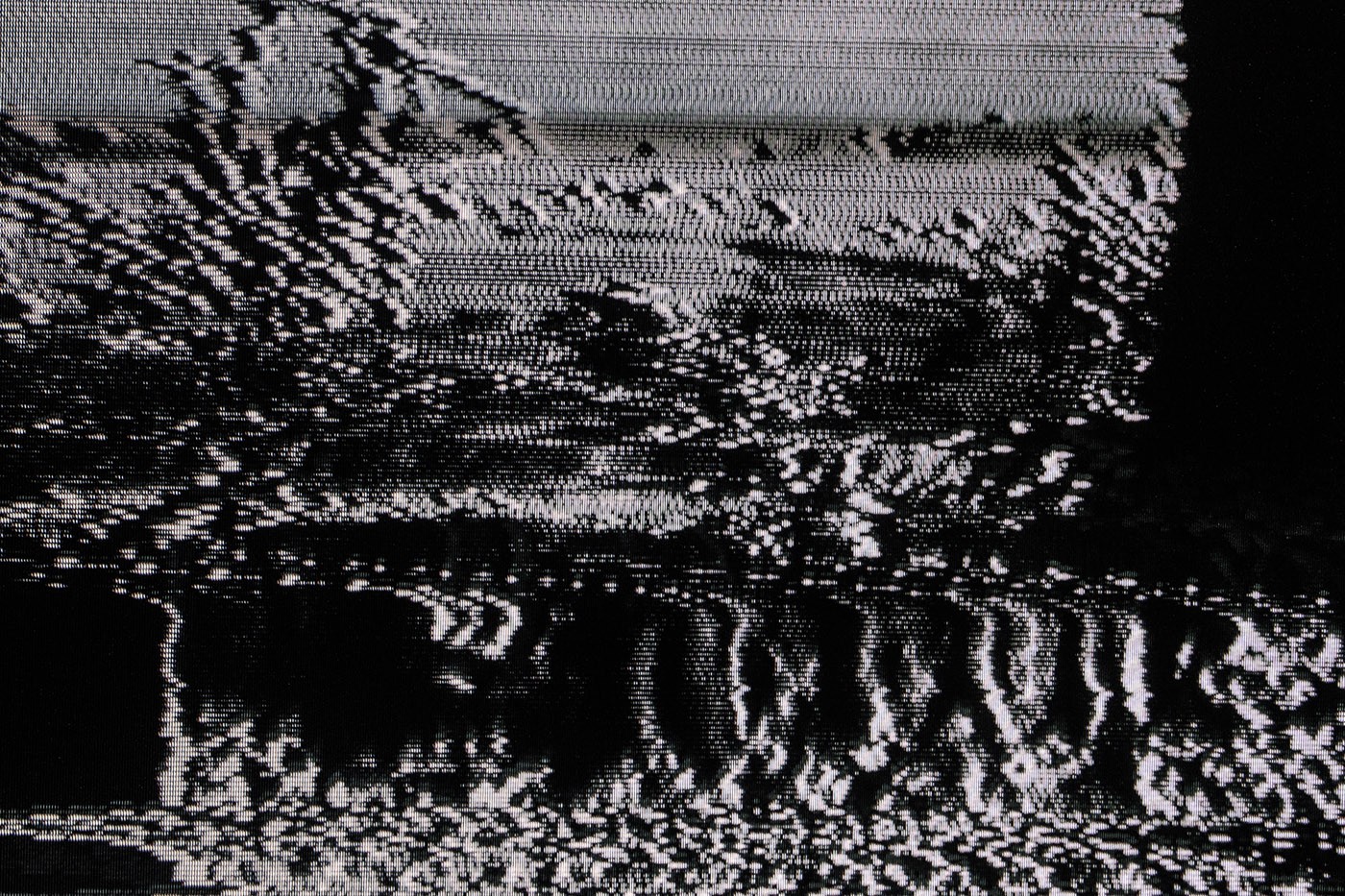

Here are some stills that were done with the previous version (identical video circuit). I captured them by recording the ARCHER's video output on a VHS tape, playing it in slow motion on a Sony Wega rear-projection CRT and photographing that with a DSLR.

Joris Wegner

Joris Wegner

Nick Bild

Nick Bild

Greg Zumwalt

Greg Zumwalt

hi, i have noticed that the capacitor C2, perhaps, could be connected backwards? will it be possible? Greetings, thanks from Santiago de Chile.