💡 Same text with images here: https://www.orcular.org/orcuscooter-en

🇺🇸🇬🇧 An automated software has been used for translatinig the text (German to English) with a few corrections afterwards. I speak English, but I am no native speaker. Please excuse if there are some strange wordings or the like.)

Why a kick scooter?

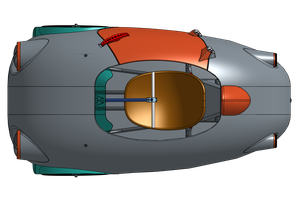

Admittedly, a kick scooter is not a new invention. However, I was initially interested in creating a product standard and first finding a product in which you find as many different manufacturing processes, materials and design principles as possible combined in one product.

A kick scooter is particularly well suited for this, since it:

- consists of different types of materials

- is manufactured using different fab lab equipment/production processes

- draws attention to the microplastic problem caused by abrasion of tires and brake pads on vehicles and thus offers potential for proposed solutions

Most importantly, a kick scooter is a popular product that numerous children and adults in cities enjoy using for daily transportation. Replacing the many conventionally manufactured kick scooters with sustainable alternatives offers potential for big impact and lots of visibility.

In a nutshell: the problem with today's products

With the orcuScooter project, I want to draw attention to several (environmental) problems and offer solutions.

Many of today's products have the following problems:

- break quickly

- are difficult to repair

- glued and fused parts of different materials (which makes recycling impossible)

- spare parts are often limited or impossible to get

Thus, many products end up in the garbage incinerator or in a landfill abroad and are simply replaced by newly purchased products.

Manufacturing often takes place in faraway countries with questionable environmental and working conditions.

Precious Plastic - why we need to rethink plastic

Plastic has a bad reputation - mostly rightly so. However, plastic is only harmful when it ends up in the ocean or forest, for example. We should also rethink plastic production of new parts from petroleum, because there is already enough of it.

But recycling plastic that already exists, endlessly, into new products over and over again, and preferably larger, fixed components that can't simply end up in the environment - that makes sense. Plastic is precious.

That's why the "Precious Plastic" project (https://preciousplastic.com/), founded in 2013, has developed several open-source machines for plastic recycling, which are also used in the orcuScooter:

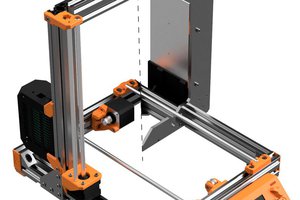

In the shredder, old parts, e.g. broken plastic parts of the orcuScooter, are shredded into small pieces. In the sheet press they are pressed into sheets. New parts for the scooters can be cut out by laser cutting or CNC milling. 3D-printed parts made of plastic are also used in the orcuScooter and can be recycled later.

Aluminum parts - Recycle, or better yet: reuse

Some parts should not be made of plastic, as they need higher strength, e.g. the handlebar or reinforcing profiles on the underside of the deck. Several CNC-milled aluminum parts are used, such as connector plates or angles. The steering rod parts are built from square profiles that are cut and drilled to size.

Aluminum is easily recyclable, but the energy required to recycle aluminum is much higher than for plastic. For this reason, aluminum parts of the orcuScooter are initially designed for "reuse", i.e. the parts are designed to be as versatile and reusable as possible - e.g. in new kick scooters or also in cargo bikes from the "Cargo-XYZ" project, from which the design is inspired. The more products that use aluminum square profiles (and there are already many of them), the greater the potential for parts that can be used again and again.

In addition, some aluminum brackets from the "Unipro-Kit" of the Open Source Ecology Germany association are deliberately used. The Unipro-Kit is an open source parts library...

Read more » Oskar

Oskar

theschlem

theschlem

gregsaun

gregsaun

Brien Allison

Brien Allison

Gonzalo P. Chomon

Gonzalo P. Chomon