Why a Braille embosser

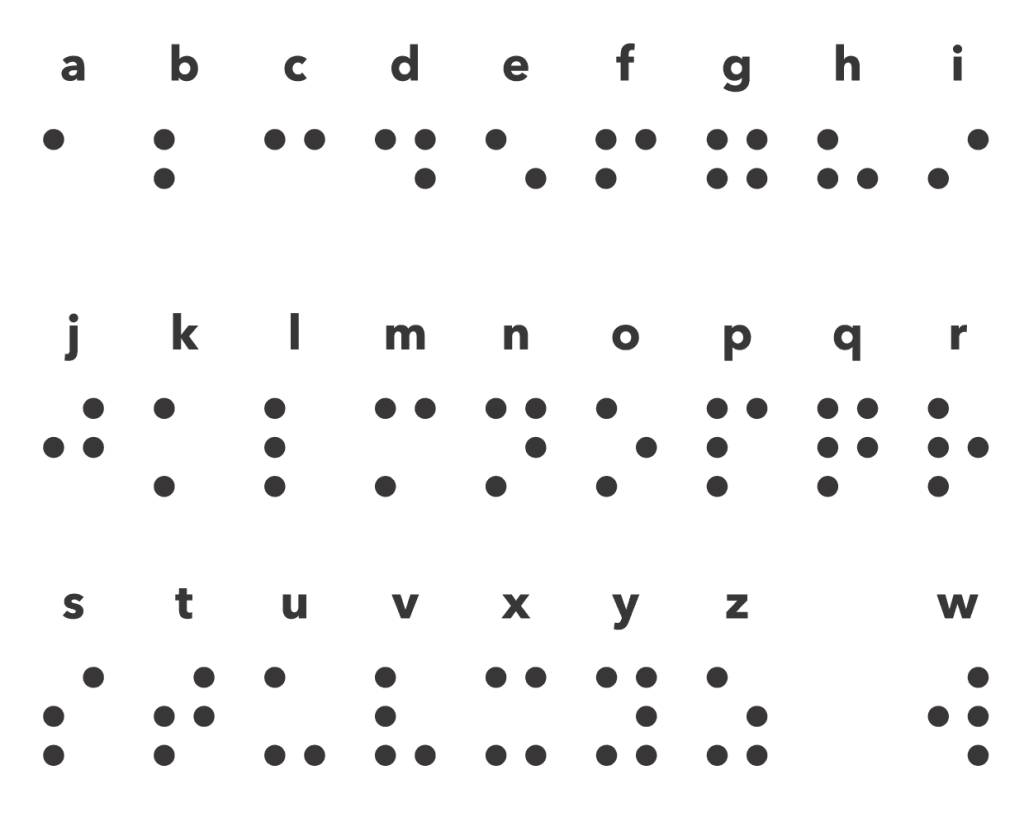

According to the World Health Organization there is 45 millions peoples living in the world with visual impairment. It's hard to get good statistics but many countries estimate that only 10% of people with visual impairment read and use Braille. But according to the same statistics 90% of blind people who are employed read and write Braille. So Braille is an important subject for education and equality.

You can get more info about the subject here https://brailleworks.com/braille-literacy-statistics/ and here https://brailleworks.com/braille-literacy-vital-academic-improvement-employment/

In rich country this would not be an issue as there is commercial solutions, the reality is not as bright as we can think, there is still an issue with general accessibility in most rich countries. Open source can be one aspect of the solution, not just because it is cheap, but because it is build together, this is about sharing and building solutions all together. Sometimes the super market at the corner don't have the right solution.

And what about countries where the average salary is about 2000$ a year. In these countries what about a rural school where there is just one or two students affected by blindness. Who will pay a year of wages for a solution. And again this is not just because open source is cheap :

- You have the schematics you can fix it.

- I you have build one in a workshop, you know how to fix it if something go wrong or you know who can fix it.

- You have the schematics, so you can adapt it to your needs, even upcycling or recycling some parts you got around. And if you adapt it, you can share.

- There is open source communities, so you can find some help.

And now that we have talk about accessibility, what about teaching technologies. What about teaching that sometimes technologies can really help people, that building a tool is not just a mind exercise. Building a tool is about making choices, what is the best solution if you need it cheap ? what is the best solution if you need it easy to build ? easy to use ? fixable ? accessible ? moveable ? And it can be fun and satisfying.

A brief About BrailleRAP story

I often thought the project started with BRAILLGO (https://hackaday.com/2014/02/24/braigo-a-lego-braille-printer/) in 2014, i was wrong, but it was the first time i was thinking "hey brilliant idea". Open sources and fablab area count many projects to emboss Braille on paper sheets.

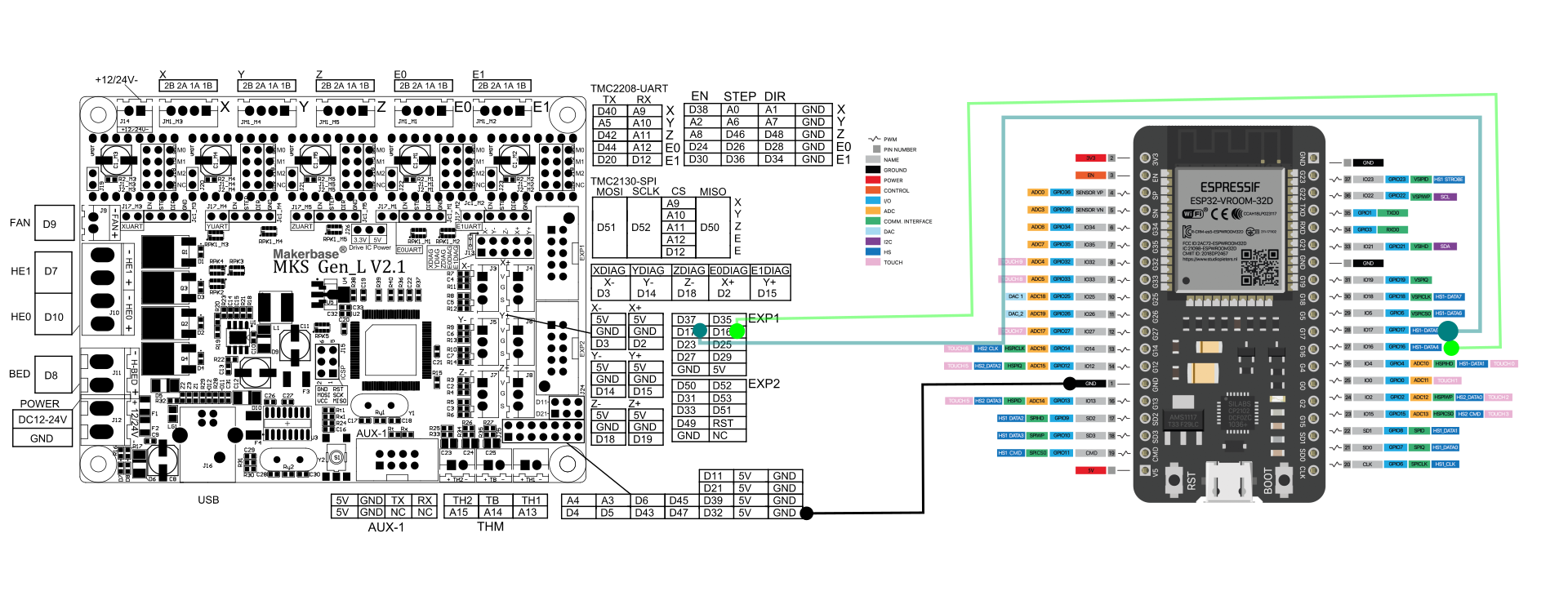

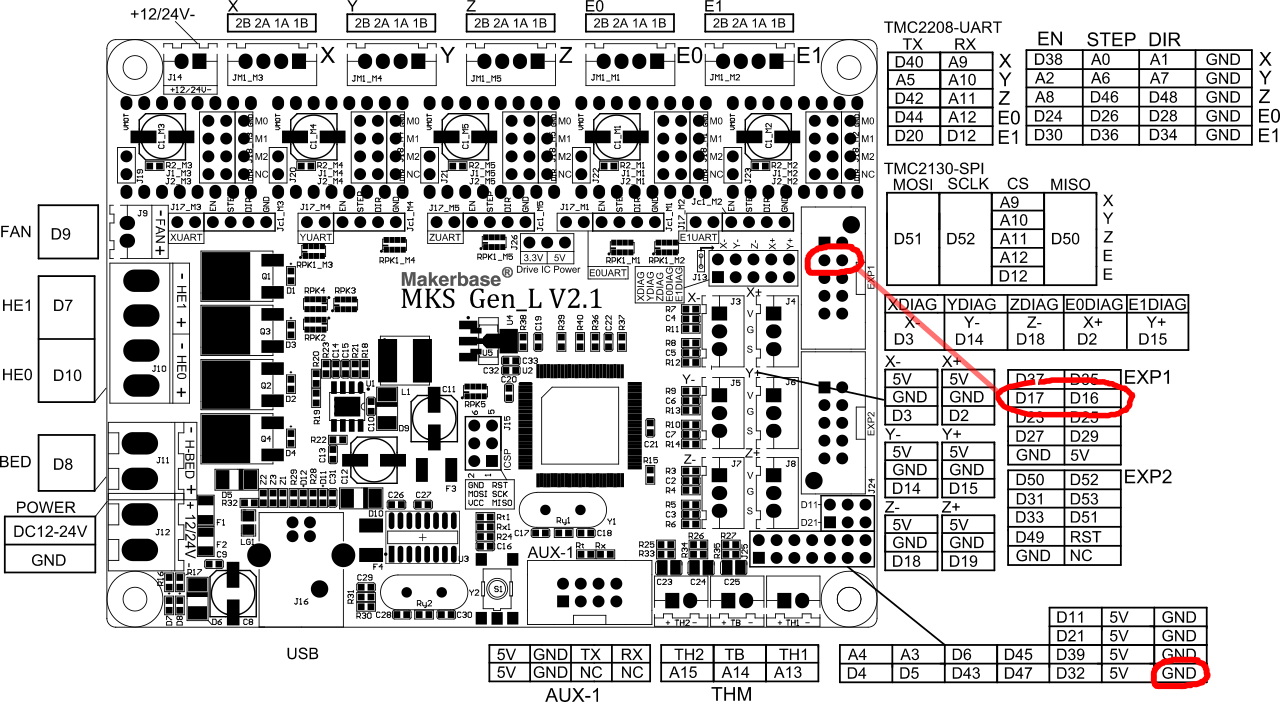

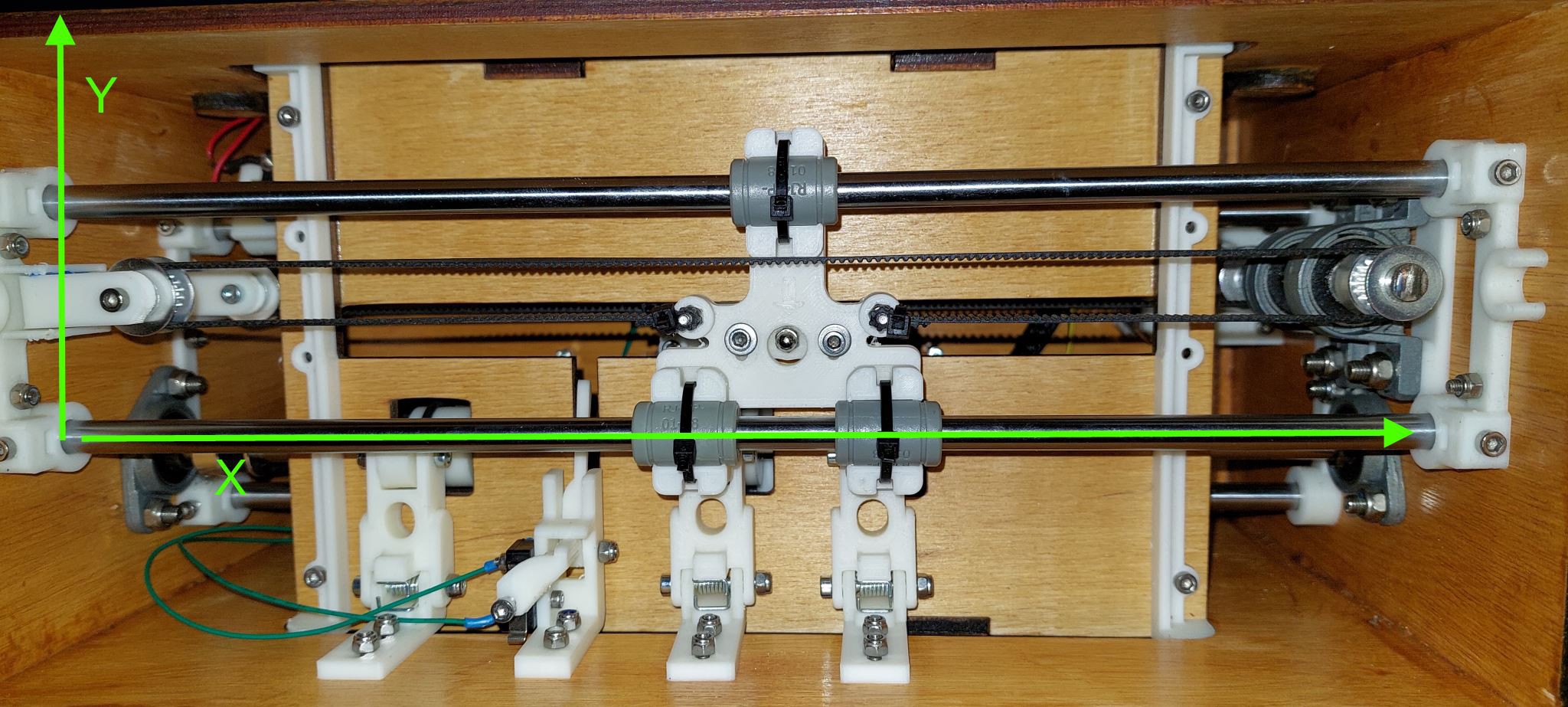

In 2016 the My Human Kit non profit organization ( https://myhumankit.org/) organize an hackathon where they started to emboss paper with hacked 3d printer. This was a proof of concept, but complex to build and hard to use.

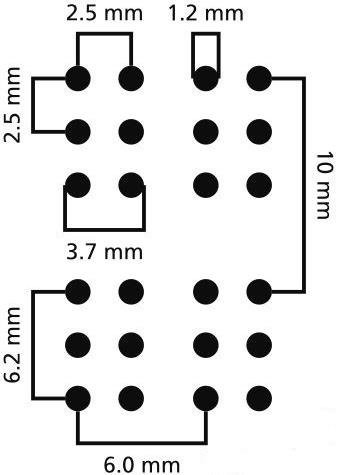

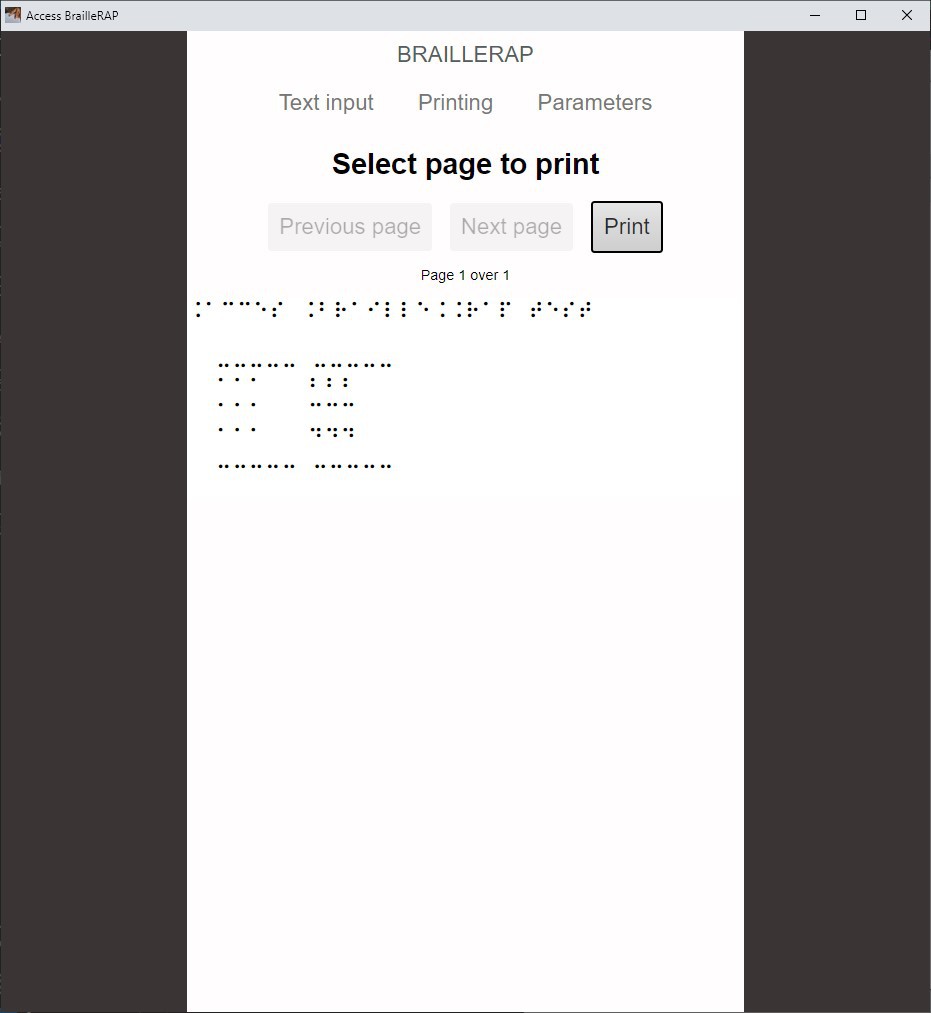

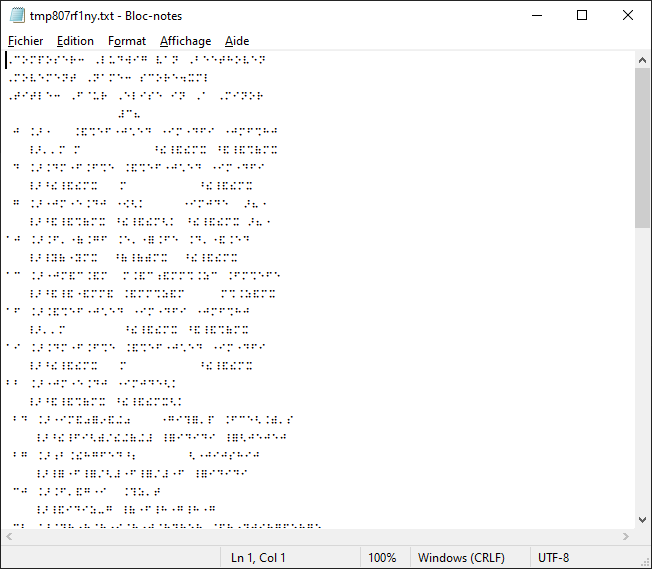

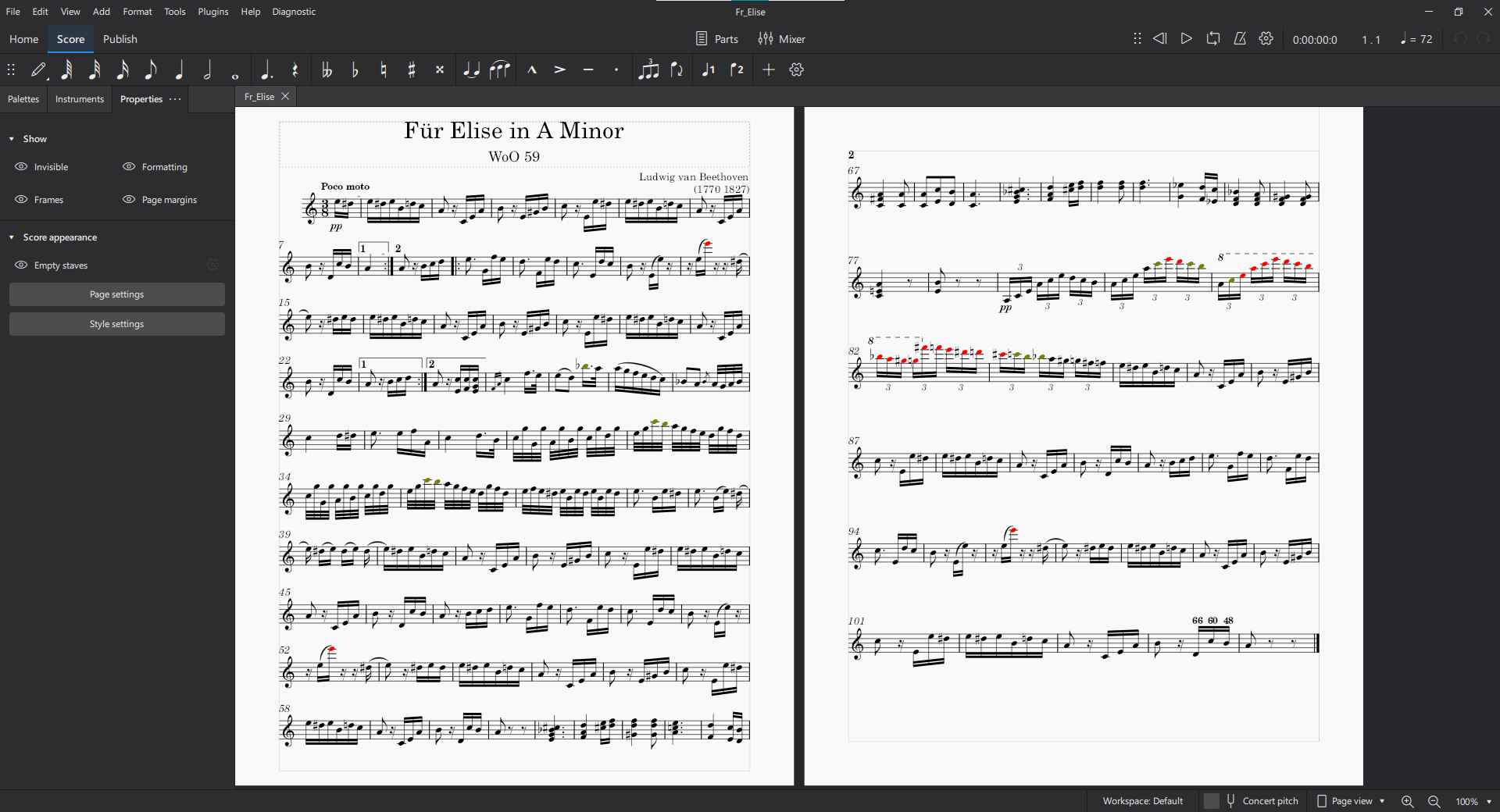

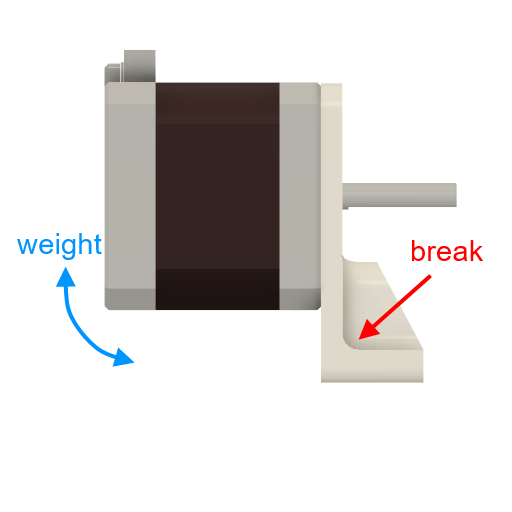

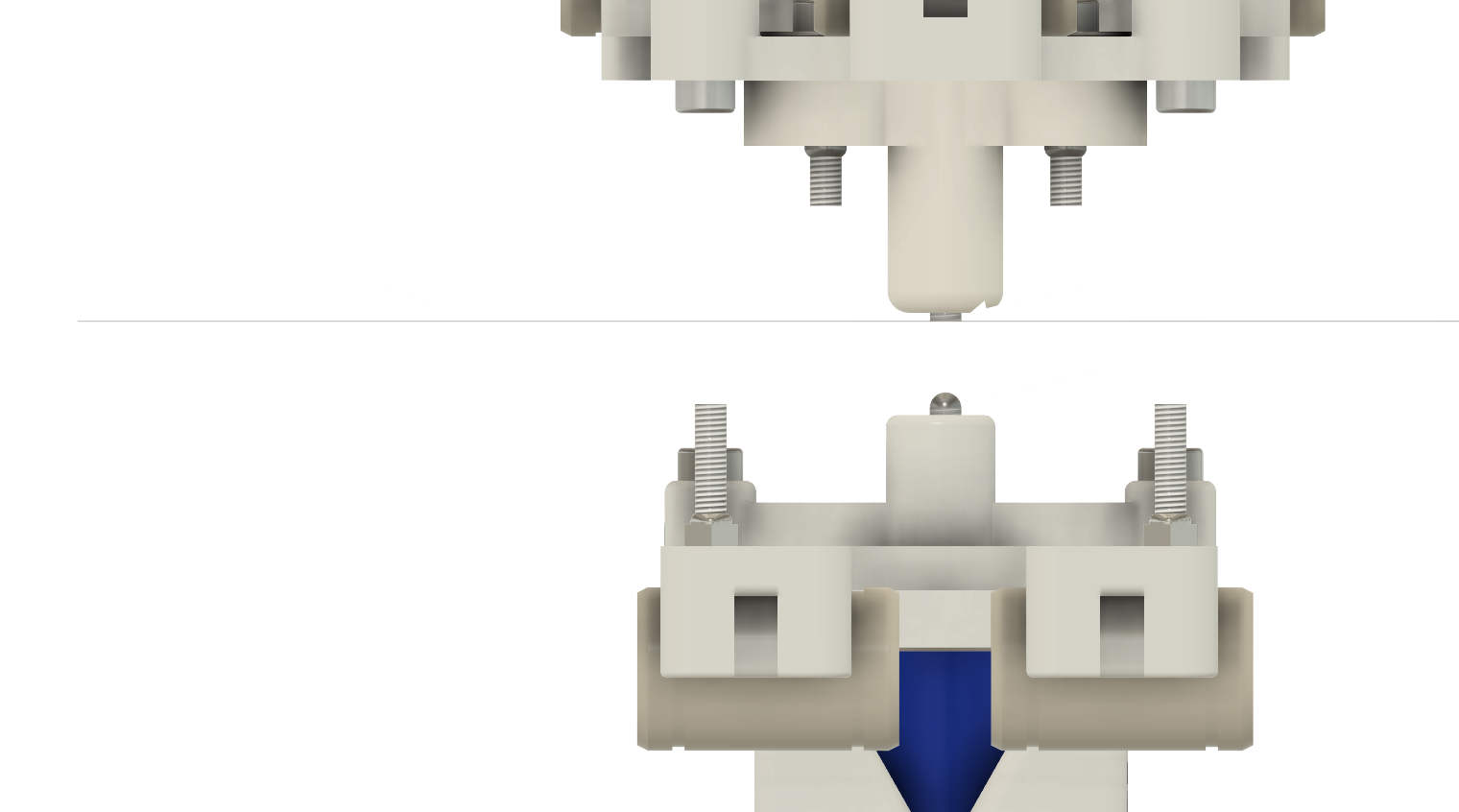

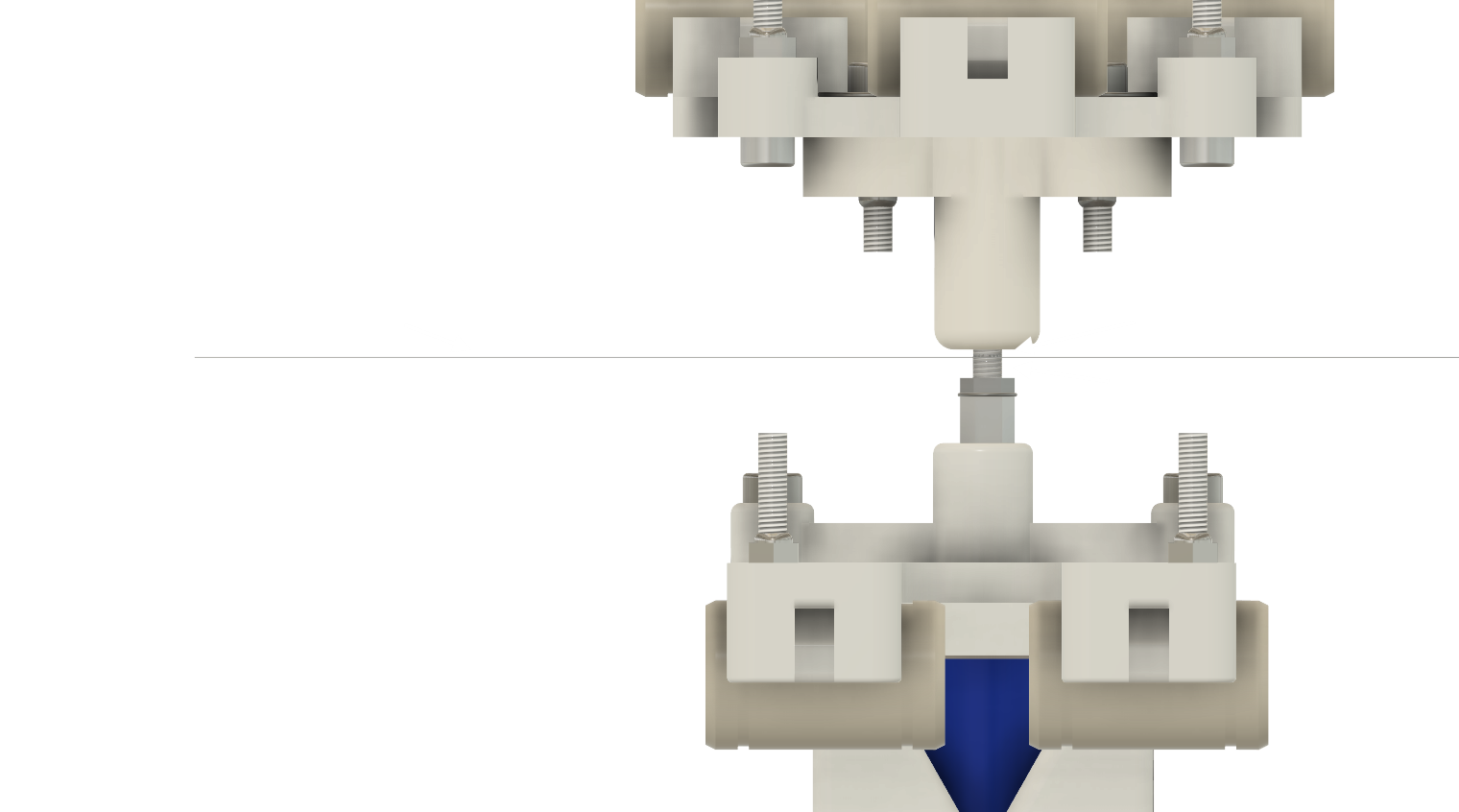

In 2018 we started BrailleRAP-SP with the idea to build a full reproducible device. A device that emboss one dot at a time but very fast using an electromagnet. A few month later, we started to show different version in makers events and non profit organization. Everybody congrats the team about the physical quality of the Braille Dots. But the lack of time, the covid crisis, some issues with NatBraille usage due to Java license evolution, the project died.

In 2022 the CCLab, a french non profit organization (https://forgecc.org/?PagePrincipale) offer to support some evolution of the design to organize workshop in Cameroon Africa, in partnership with ANIAAC, a local cameroonian non profit organization, and funders, Orange Fondation and My Human Kit. With the CCLab and some enthusiasts we started the BrailleRAP project.

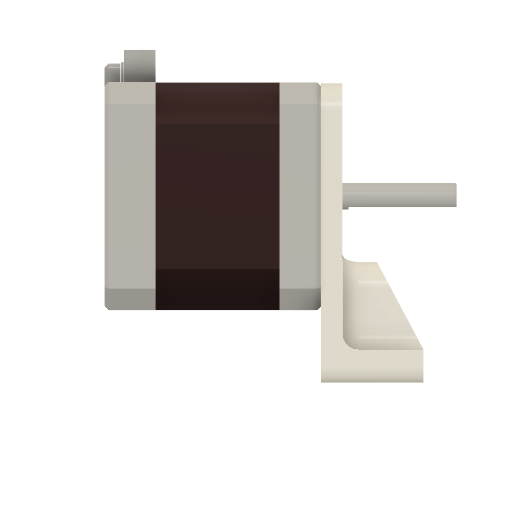

The BrailleRAP contribution

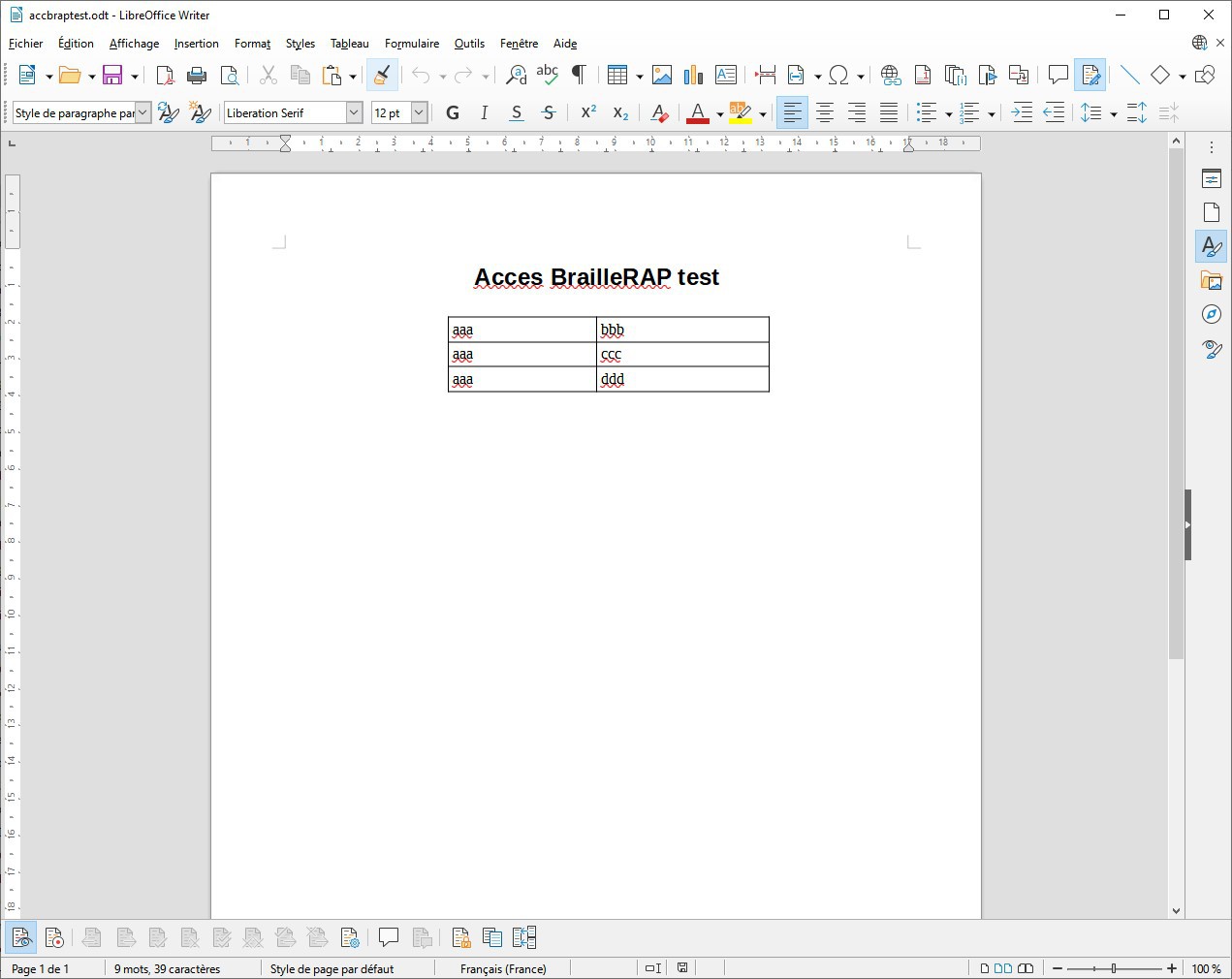

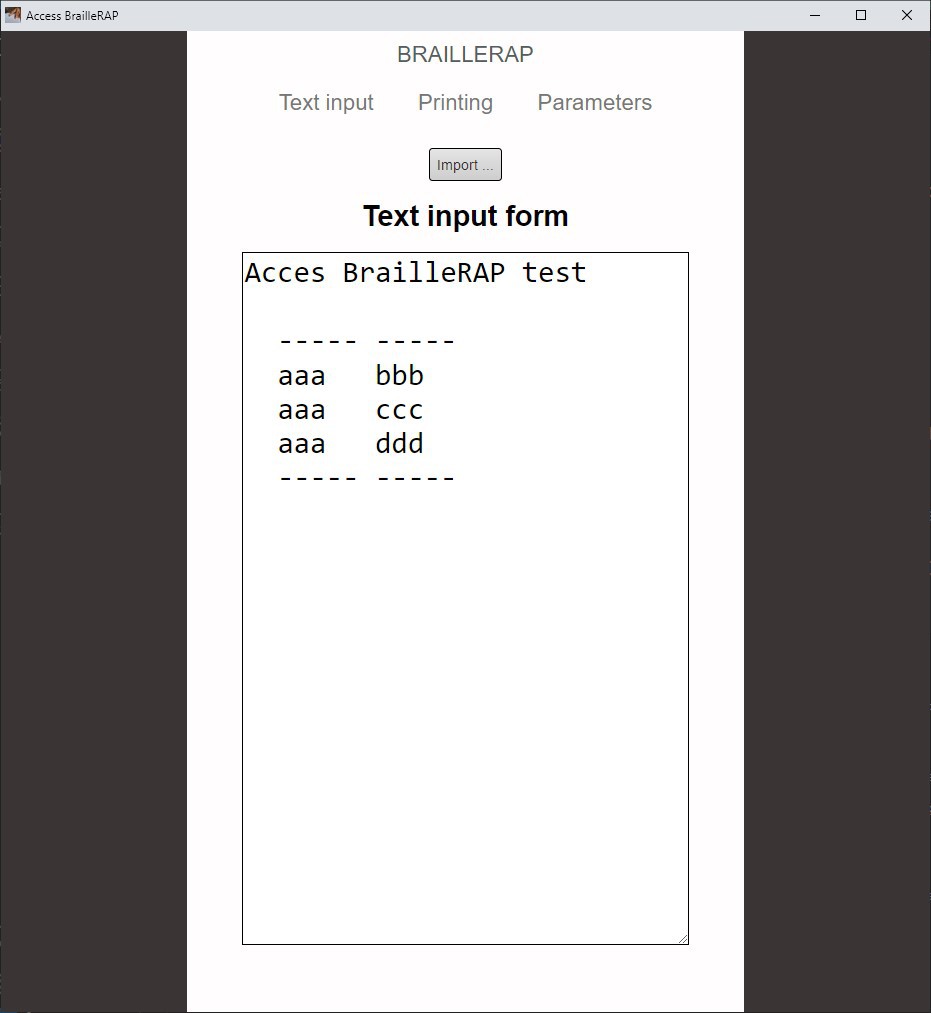

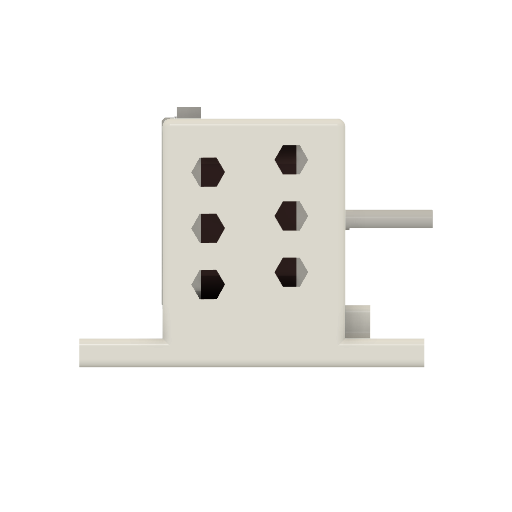

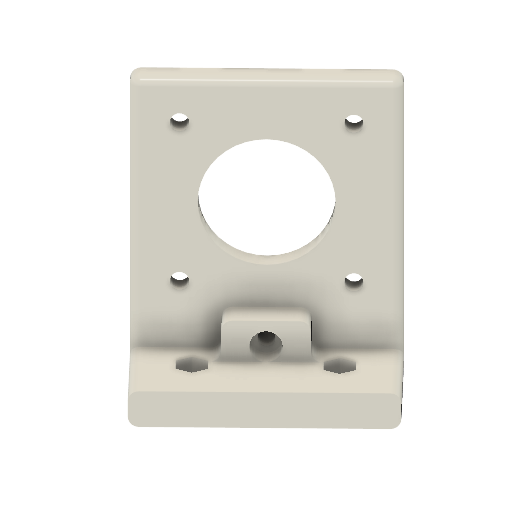

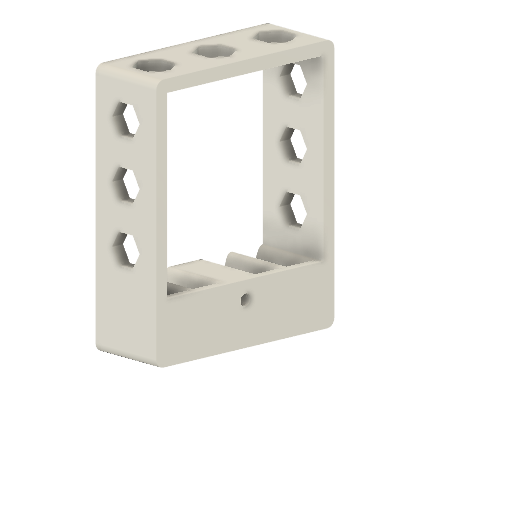

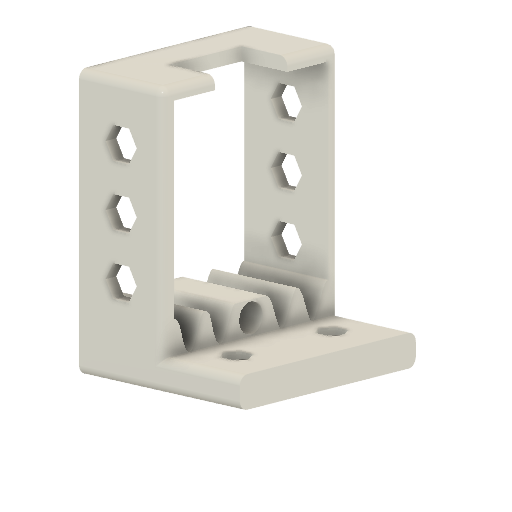

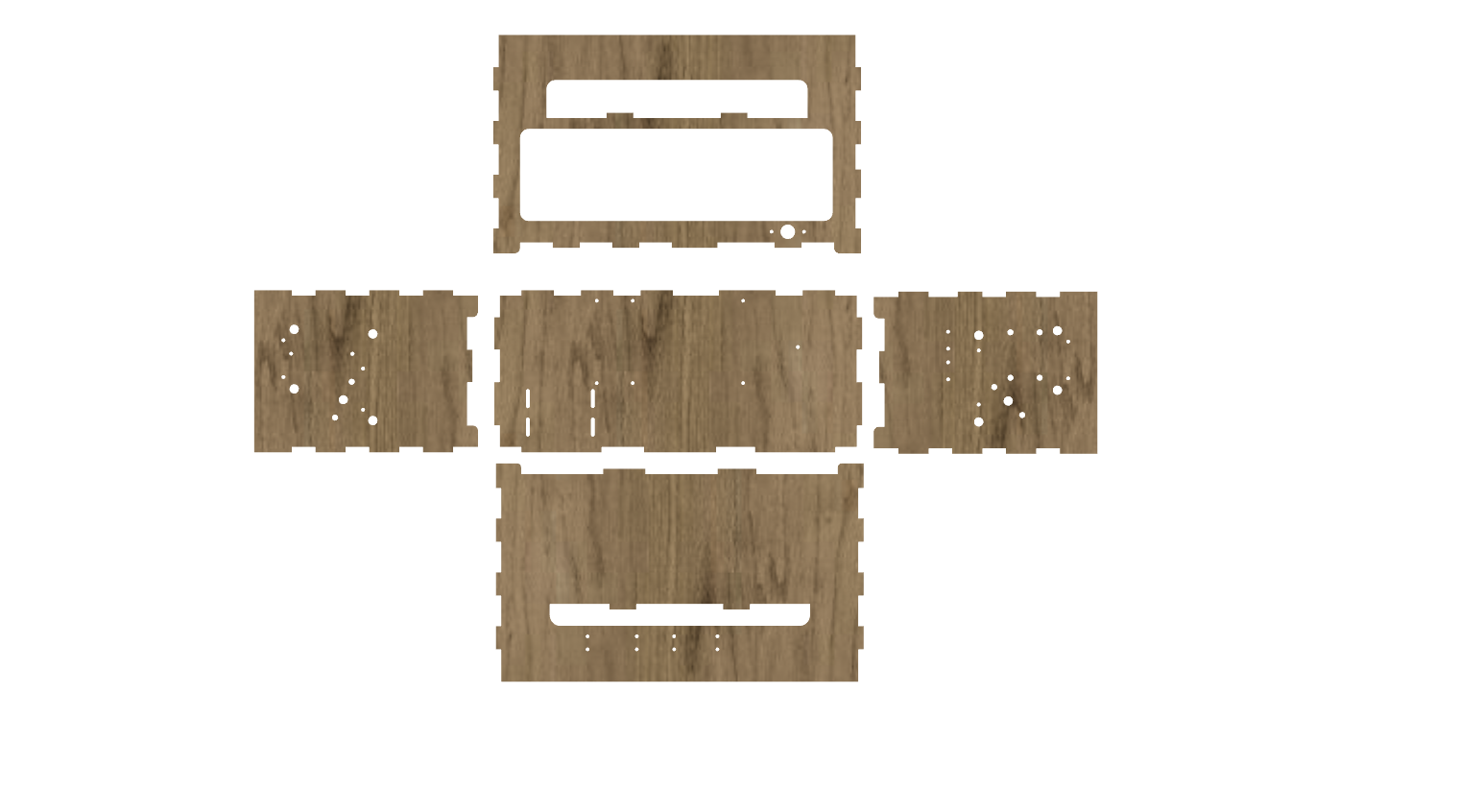

One of the idea was to improve the reliability of the paper feeding. We redesign the paper travel by lowering the output of the paper, giving us the opportunity to delete a big printed part (10 hour of print x 2) that was supposed to rise the paper just after the electromagnet. We also upgrade the 2 carriages to use zip tie to...

Read more » Stephane

Stephane

Danny

Danny

zst123

zst123

Timescale

Timescale

looking good and interesting, well detailed explanation about the project.

regards

Julia

owner of

https://apkscent.com/worms-zone/