Agrofelis Robot

Multipurpose Energy-Dense, Implement Carrier Agricultural Robot.

A Programmable, AI-Ready Precision Agriculture Base Vehicle.

The Problem

The convergence of declining demographics, economic disparities, rising energy costs and supply chain disruptions in the West and the looming specter of climate change has created a perilous confluence of issues particularly impacting agriculture and public safety.

In the agricultural sector, farmers are experiencing growing difficulty finding seasonal farm workers while also having to deal with the escalating costs of cultivation, which results in marginal profits, unharvested crops, and even abandoned farms. To combat these hurdles, there is an urgent need for an affordable and efficient platform that bridges the gap between traditional tractors and handheld tools and multiplies an unskilled farm worker's productivity. This imperative solution is crucial for small-scale farmers in order to safeguard their existing agricultural capital.

Moreover, the repercussions of climate change have increased the likelihood of wildfires. As fire departments confront more frequent fires, the necessity for an affordable vehicle that can serve in an integrated role with firefighting units in rural areas to reduce workloads and provide standoff safety from heat exposure is critical. A production line for firefighting robots could prove a real business challenge because of low utilization of the vehicles (typically under 100 hours/year), and a number of fire fighting departments have resorted to DIY solutions.

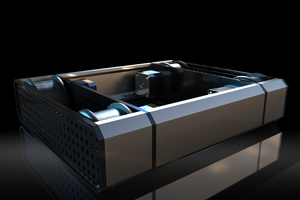

Existing vehicles on the market that can serve as adaptable platforms for various tasks are either prohibitively expensive or just not available. So it is essential to offer the ability of manufacturing a low-cost base vehicle within local machine shops, in single units or small volumes, that has a small footprint, is energy dense and agile and holds the potential to tackle localized challenges in agriculture and public safety sectors. The proposed, prototyped and open-sourced robotic vehicle system attempts to address those needs through the variety of applications in those fields in the lowest possible cost and could be utilized and manufactured by individual farmers, agricultural cooperatives, fire departments, municipalities, and beyond.

The Technology Considerations

The majority of technical solutions proposed for agricultural robotic systems aim for high levels of autonomy by using satellite positioning systems such as RTK GNSS (Real-Time Kinematic Global Navigation Satellite Systems), cameras and LIDAR sensors for achieving Simultaneous Localization And Mapping (SLAM), as well as supplementary systems like radars, odometers and inertial systems.

In the case of RTK GNSS, signal interruption due to foliage, weather conditions, or a lack of ground stations limits its usefulness. LIDAR, on the other hand, can be combined with odometers, cameras and IMUs, with no reliance on external signals. Additionally, the use of cheaper 2D LIDAR on a tilting mechanism allows 3D coverage with considerably lower cost. The strategic selection of LiFePO4 batteries offers endurance in high temperatures, in-combustibility, utilization of non-toxic materials, the ability to work unevenly charged and a slow rate of self-discharge. Introducing a remote control system capable of automating certain operations through recording and replaying can offer an affordable alternative suitable for smaller platforms, while also having a broader applicability and offering a considerable boost in overall productivity.

The Potential

Within the scope of an agricultural vehicle, a variety of technologies could be integrated, encompassing implements such as:

- Grass Cutter/Lawn Mower: A frequent and necessary application in orchards.

- Turbine Sprayers: Beneficial across orchards and vegetable cultivations for dispensing pesticides or water-soluble fertilizers.

- Fog Sprayers: Enabling extended reach...

igorfonseca83

igorfonseca83

Josh

Josh

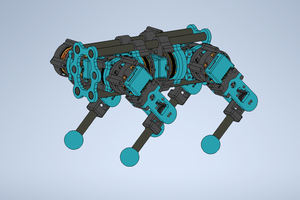

Aaed Musa

Aaed Musa

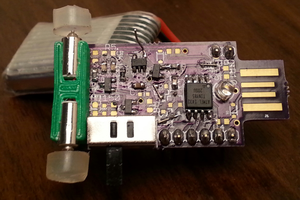

NEBRA Labs

NEBRA Labs

Thank you Victor !!!