-

1If you get a Jumperless Kit (or order your own boards with SMD parts assembled)

The assembly is pretty easy, it's all through hole stuff.

Here's a montage of all the steps to give an overview of what you'll be doing

If you've gone through the trouble of ordering your own boards and everything, I'd be happy to send you a free set of spring clips, which is the only part with a huge minimum order quantity and having them made was a whole thing.

![]()

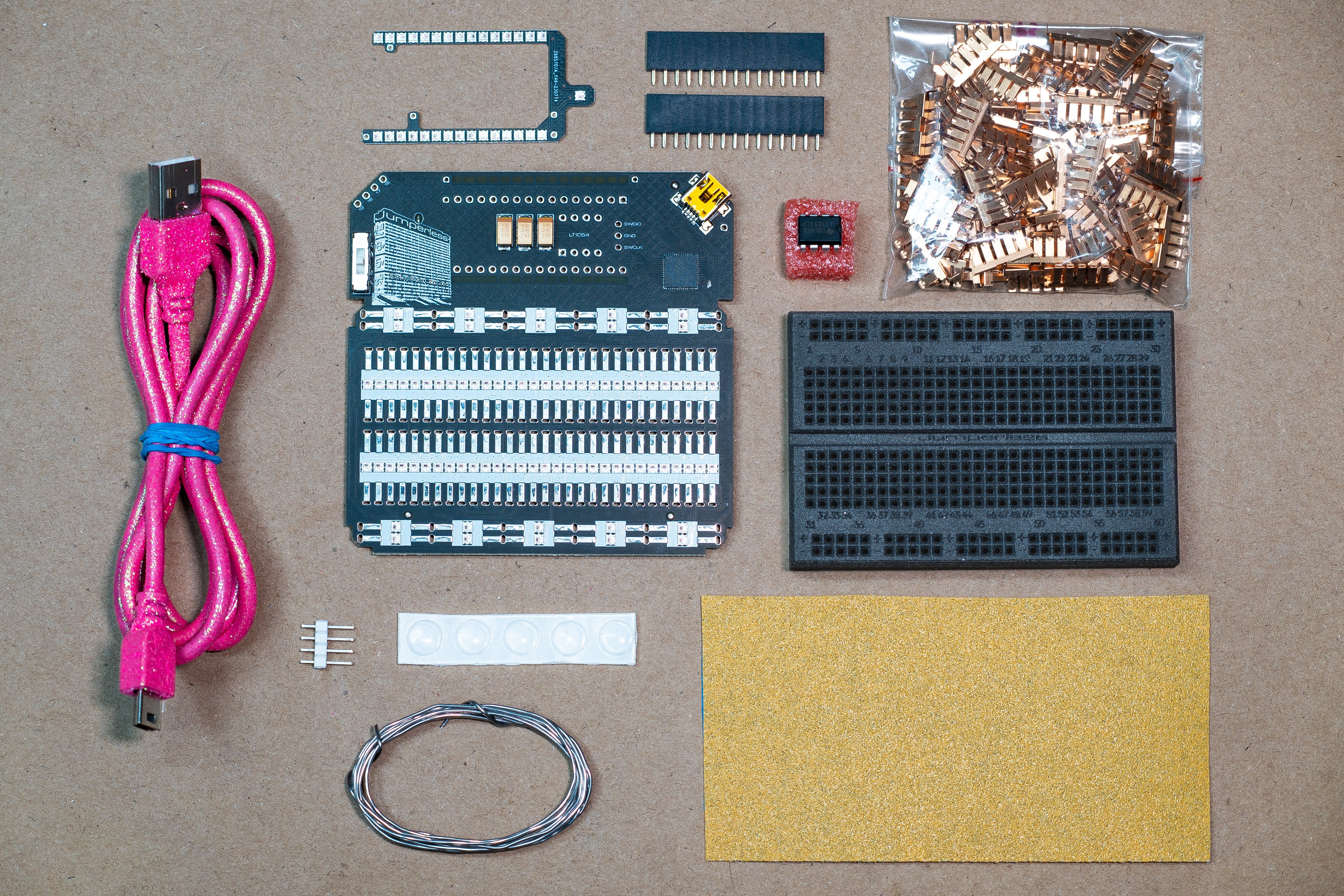

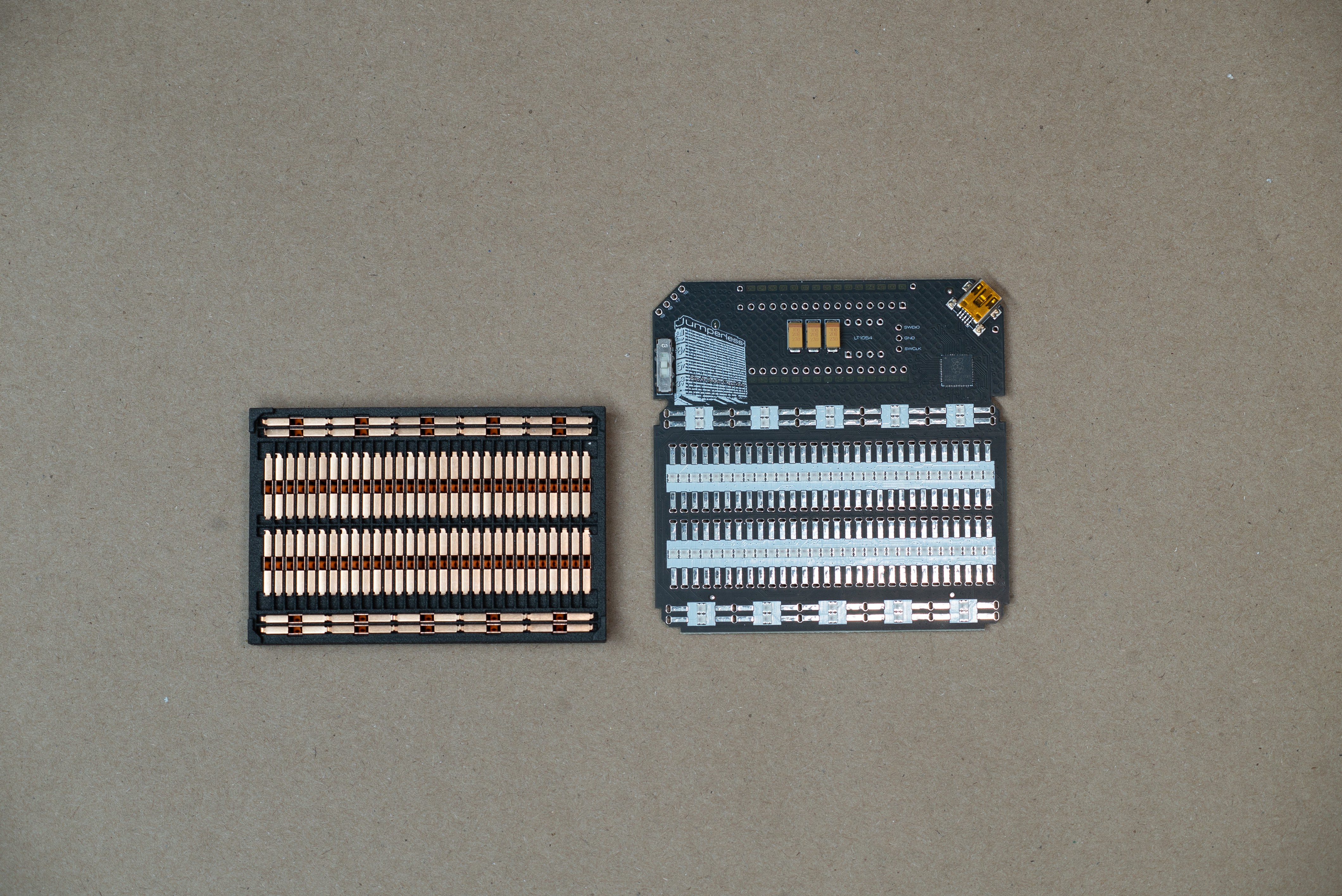

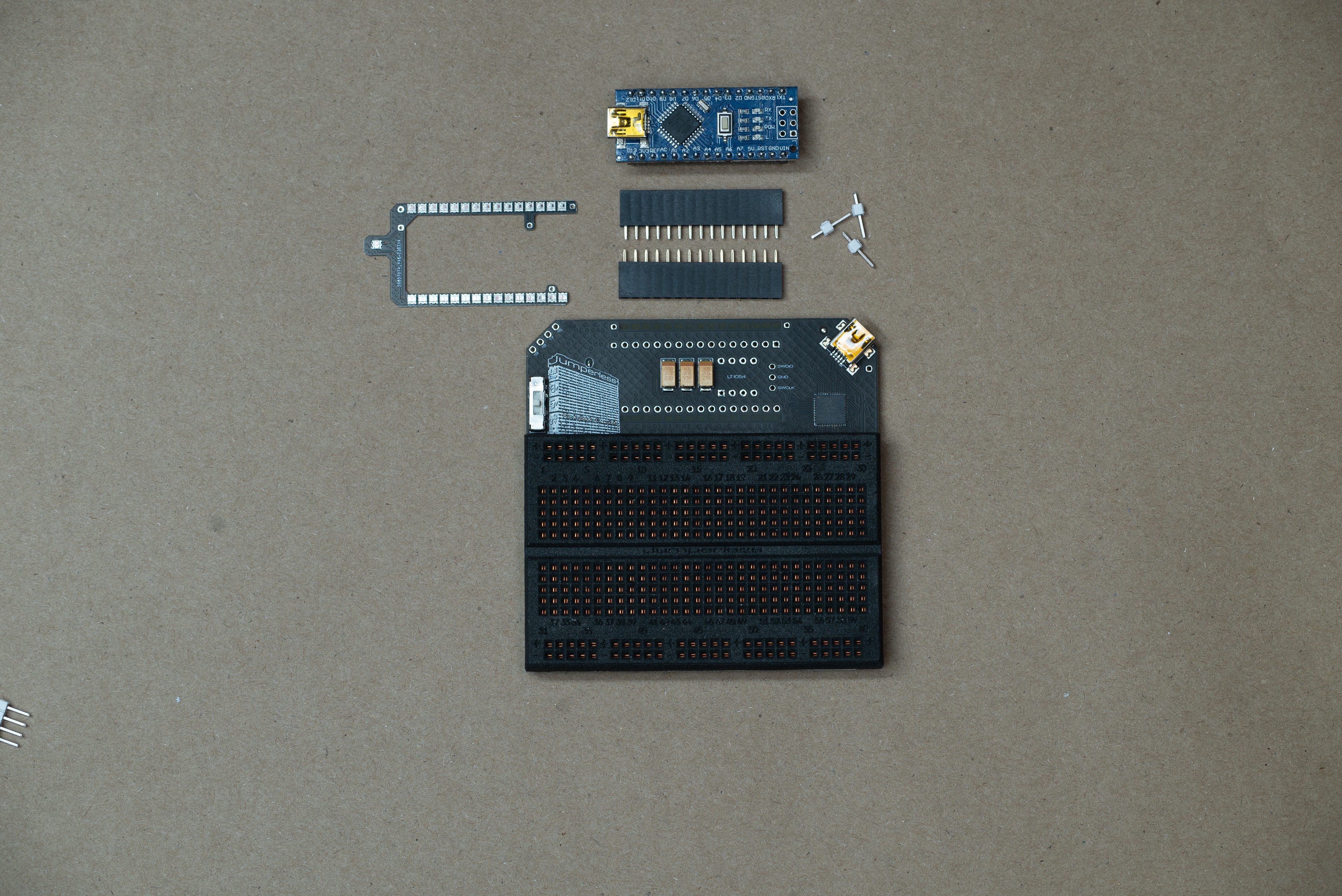

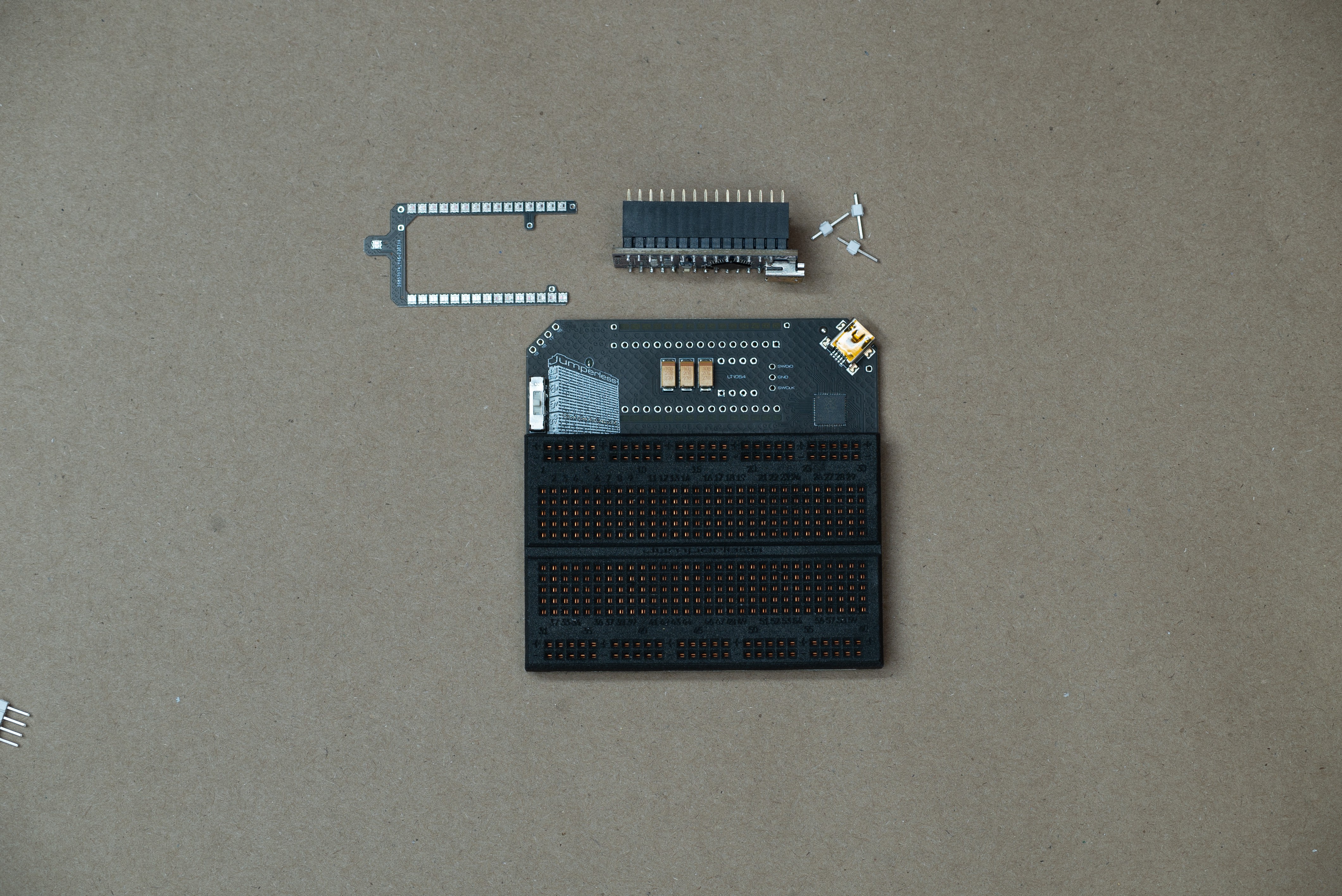

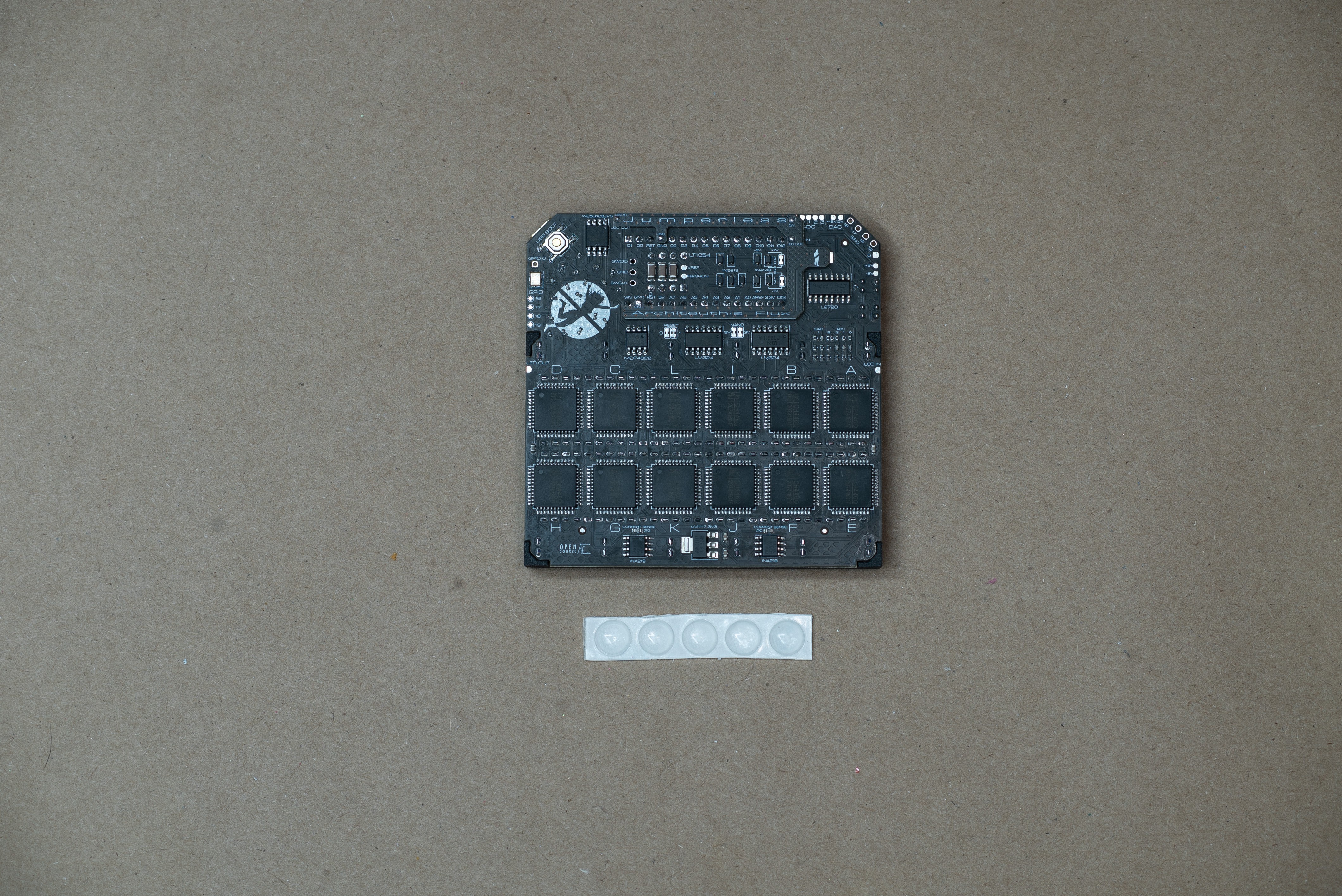

Your kit will come in ~7 parts:

- Main board (all the SMD stuff assembled)

- LED “wishbone” board (the LEDs around the header that shine through the board)

- 2 x 15 pin female headers

- Plastic breadboard shell

- 80 x breadboard spring clips

- 1 x LT1054 in 8 pin DIP

- 4 x Sticky-backed rubber feet

I also include some:

- sandpaper

- masking tape

- ~4 feet of solder.

The reason I'm including solder is that when you're just starting out with electronics you think soldering is hard. It isn't, you've just been using crappy solder and no one told you how big of a difference it makes. So I include ~4 feet of Kester Sn63Pb37 0.8mm Type 44 solder, also known as, "the good shit."

The only things you'll need to provide yourself won't be consumed in the process, you can have them back when you're done:

- A soldering iron

- an Arduino Nano (or something with the same footprint to keep the headers aligned while soldering)

- 80 pins worth of .1" male headers. You need these to stick in the breadboard while soldering to make sure all the clips stay perfectly straight, if you don't have enough, just stick anything (DIP chips, Arduino Nanos, whatever) into all the holes and that should work fine.

- some Isopropyl alcohol or flux remover spray (okay I guess this does get used up)

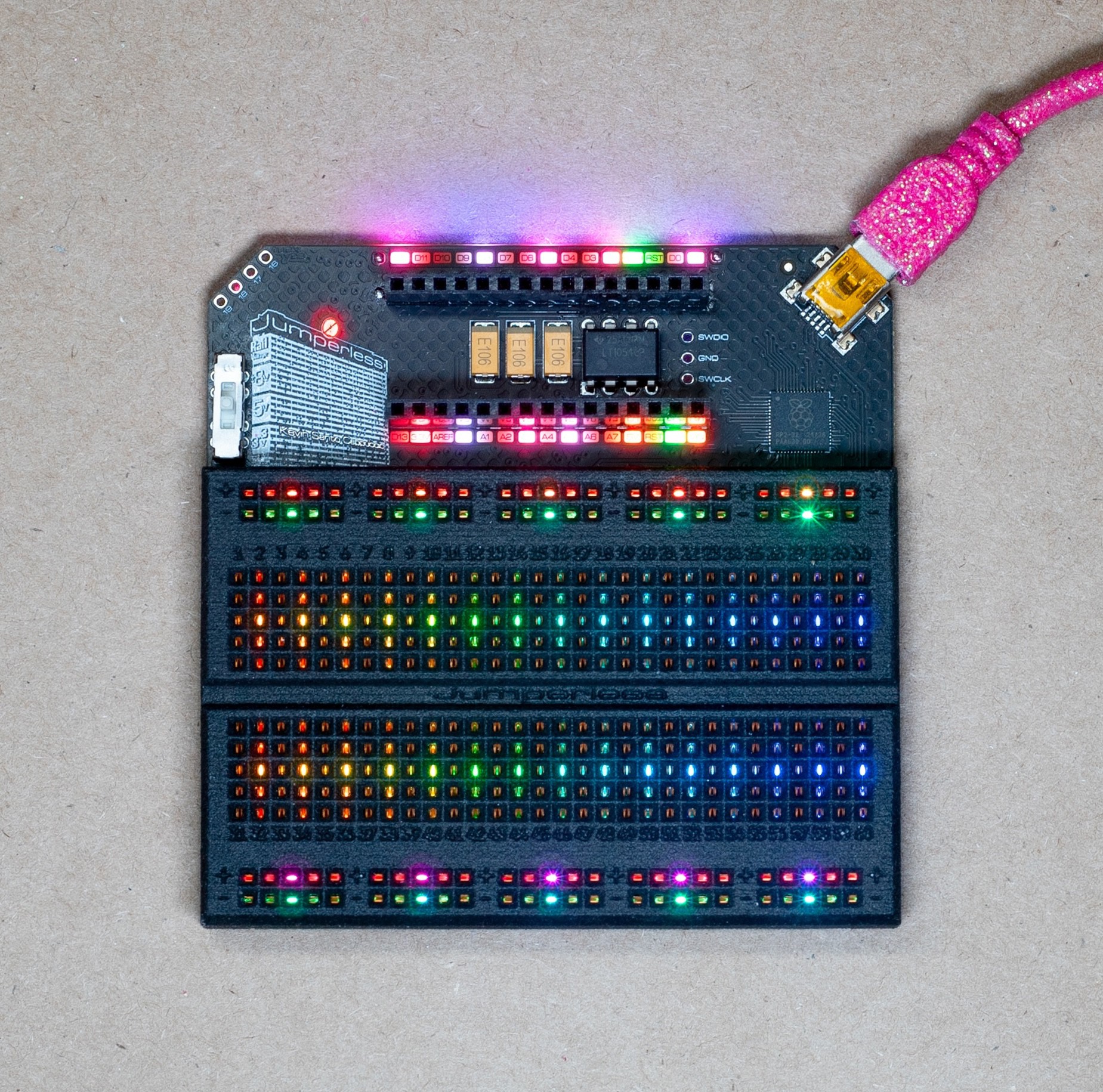

If you're the kind of person like me who wants to constantly test your board while you assemble it, you can load this LEDtesterFirmware.uf2 (just click Download Raw File) onto your Jumperless (scroll to the bottom for a guide on that). This firmware will just constantly run LEDbounce(); so you can make sure all the LEDs are working. It will look like this:

Let's begin!

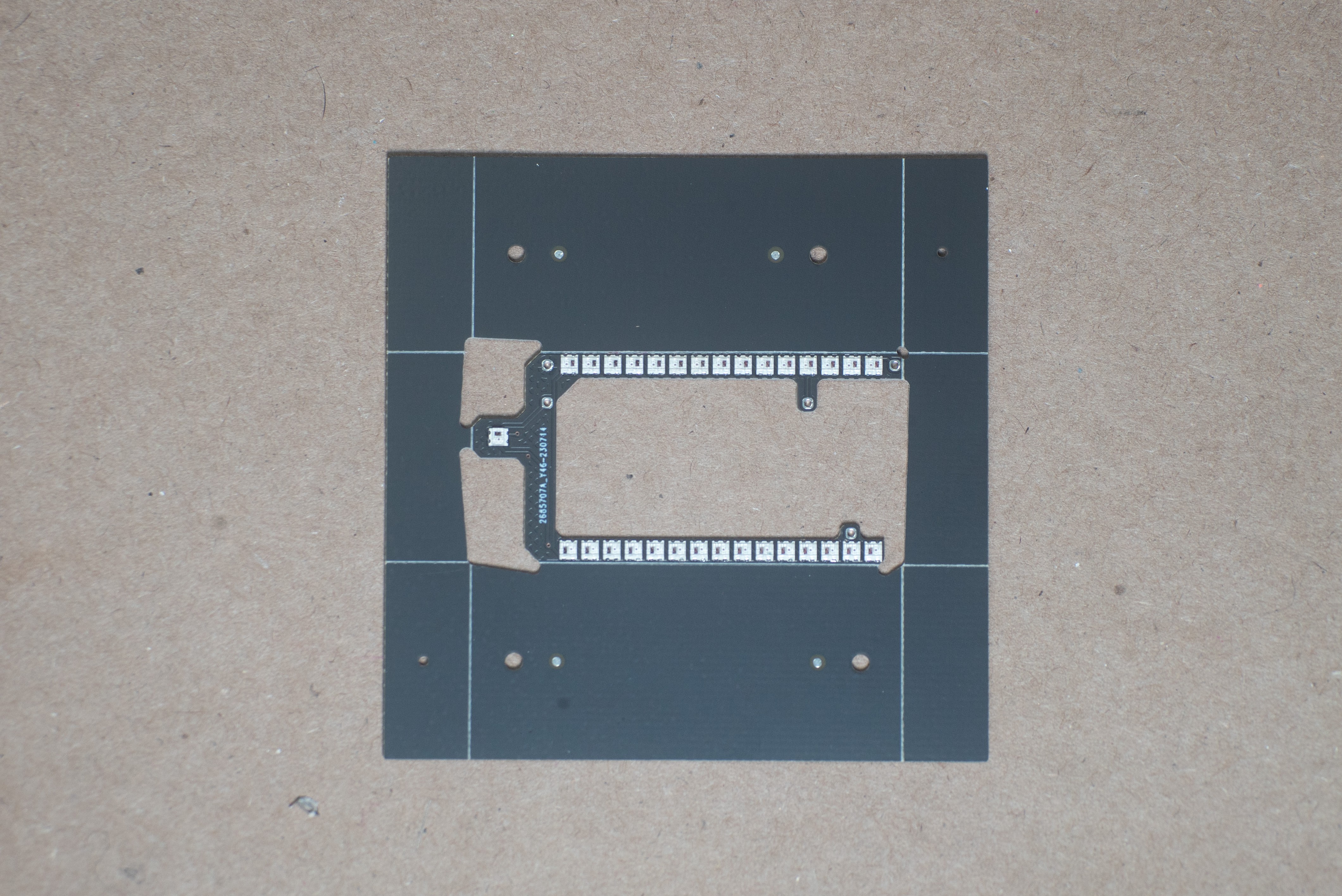

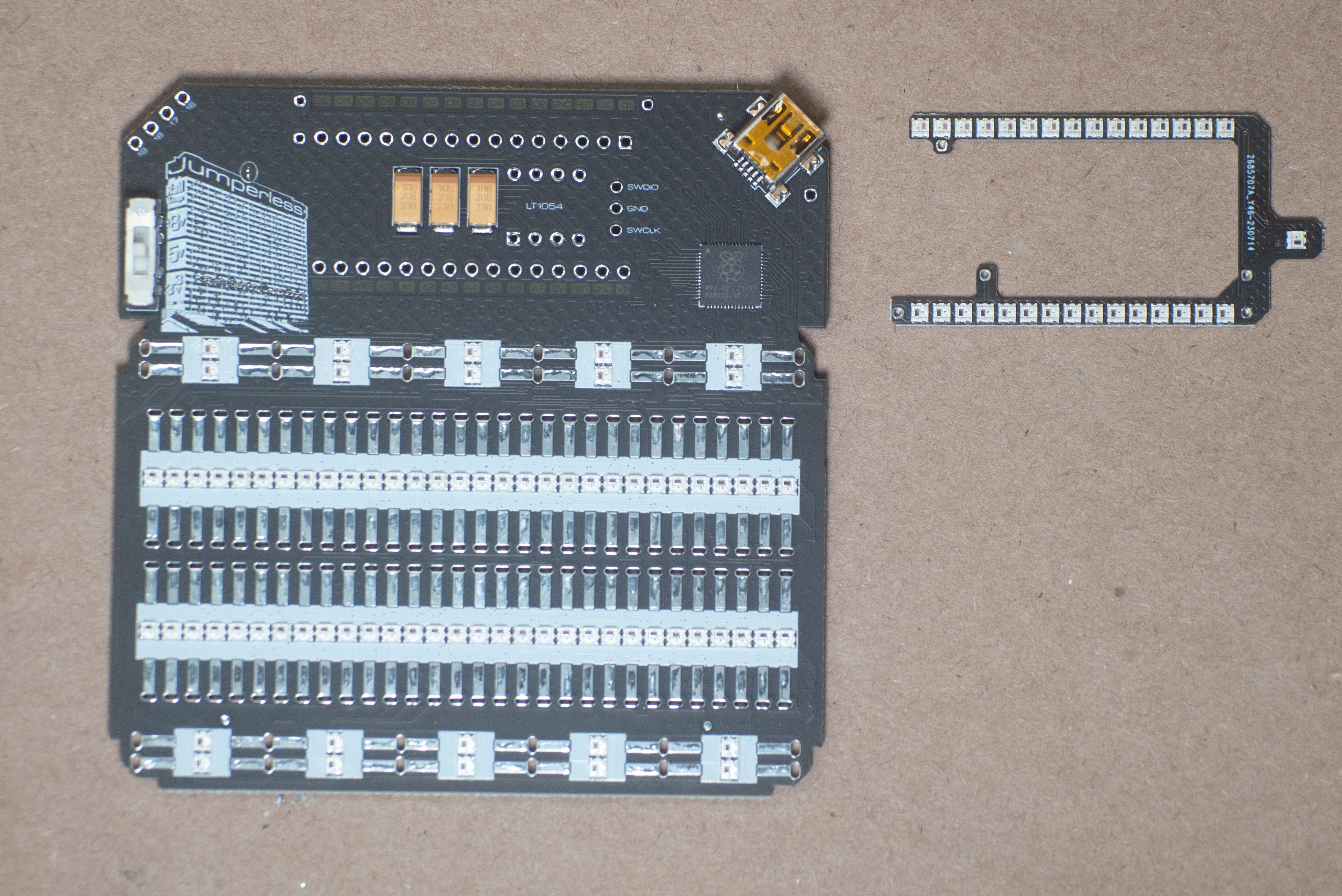

- Carefully snap of the edge rails from the LED wishbone board. Put the V-cut on the edge of a table and slowly bend it until it breaks off.

![]()

![]()

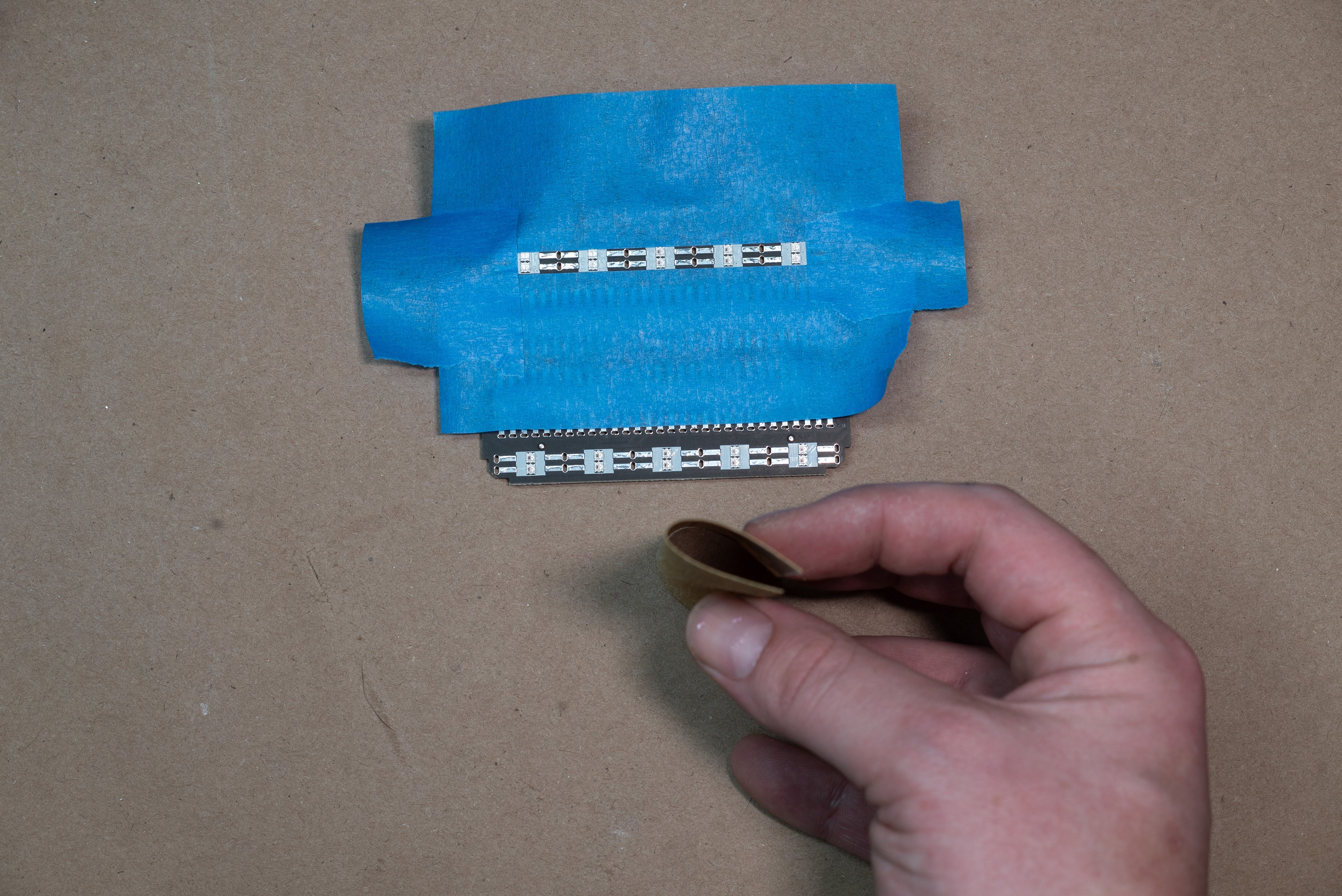

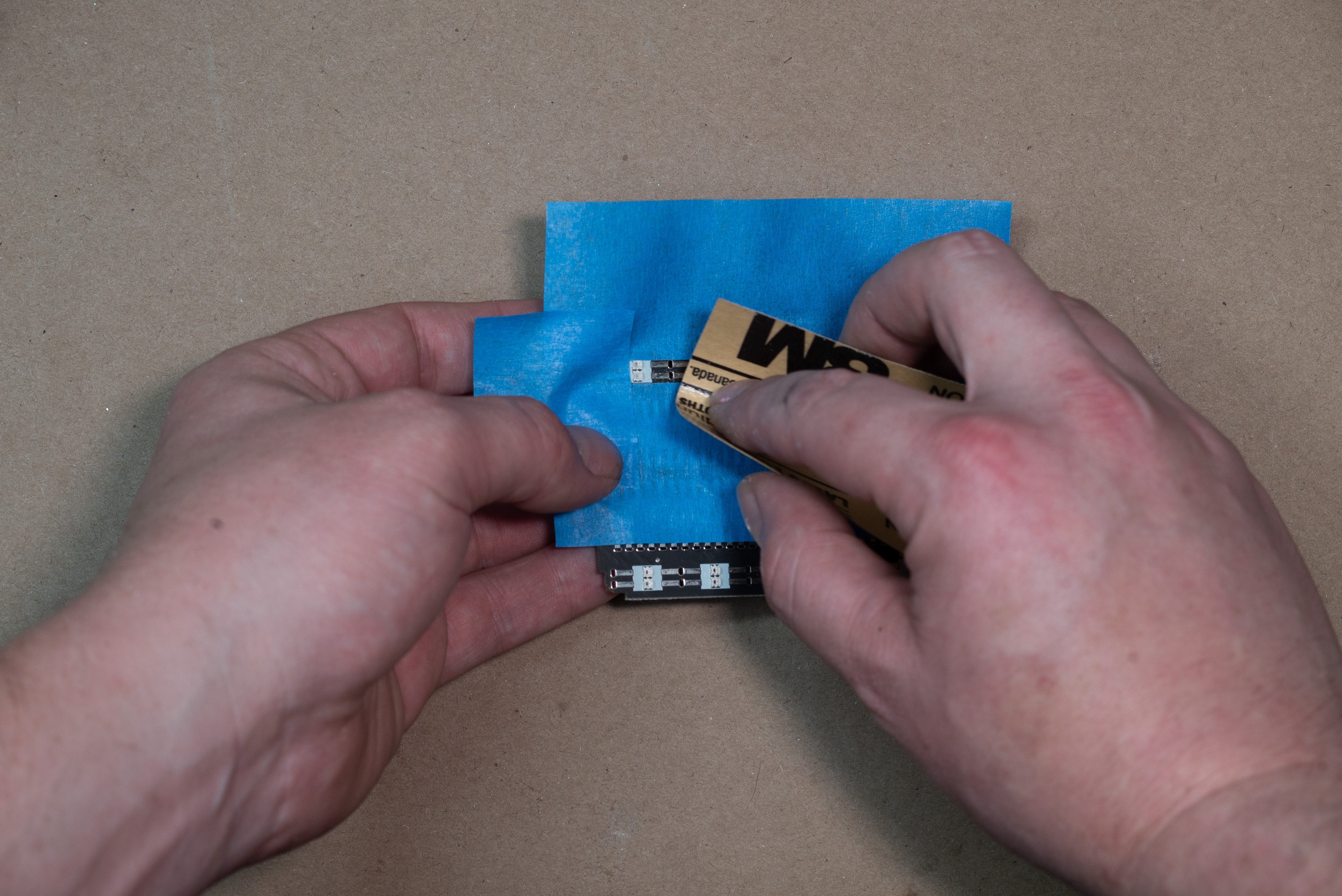

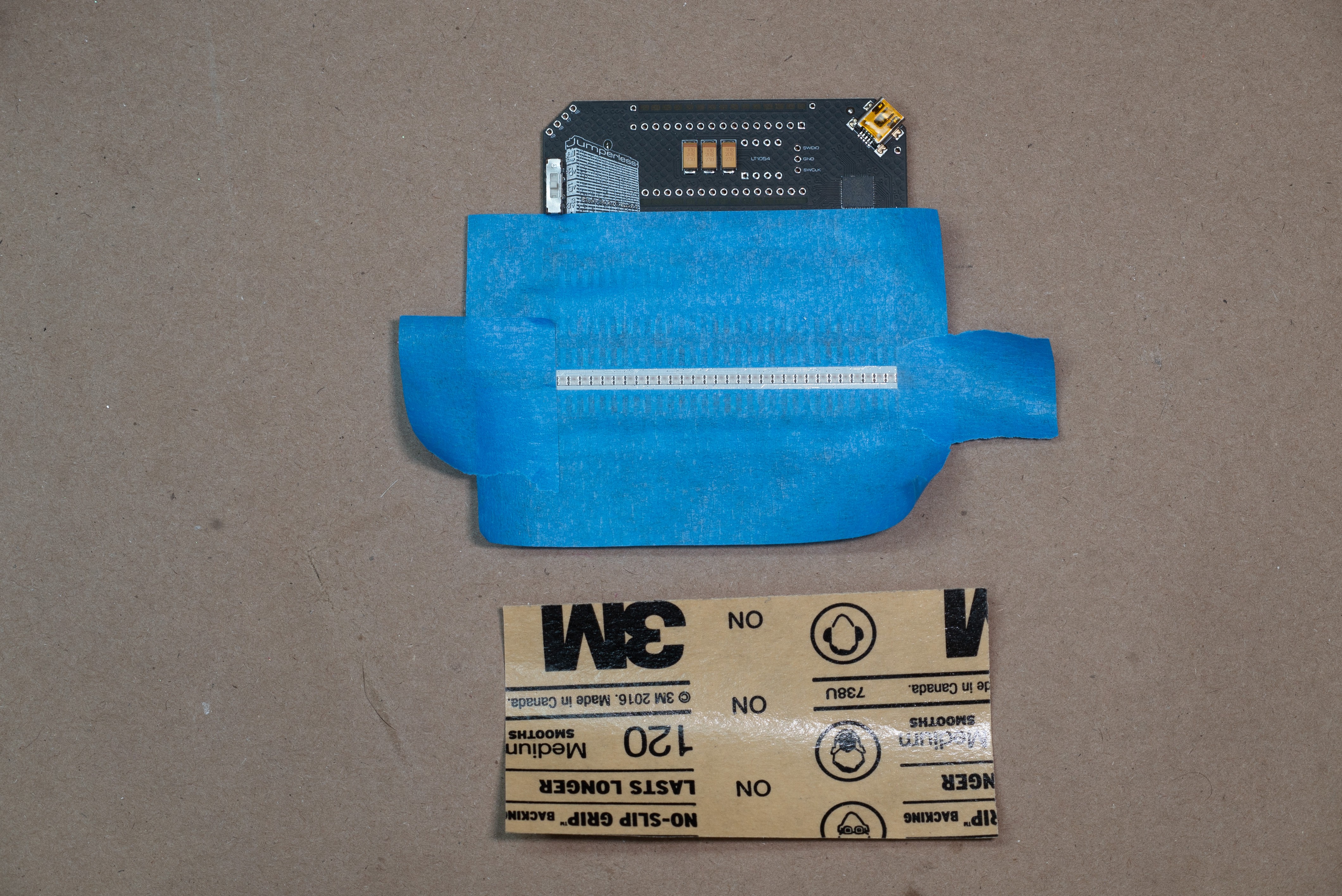

- Use the 300 grit sandpaper lightly on the tops of the LEDs on the main board to diffuse the light a bit, you don't need to do this on the reverse-mounted "wishbone" board. You can use masking tape so you don't accidentally sand the board for aesthetic reasons (but there are very few traces on the top layer and you shouldn't be sanding hard enough to break a trace.)

![]()

![]()

![]()

When you're finished the LEDs should look like this (before is on the left)

![]()

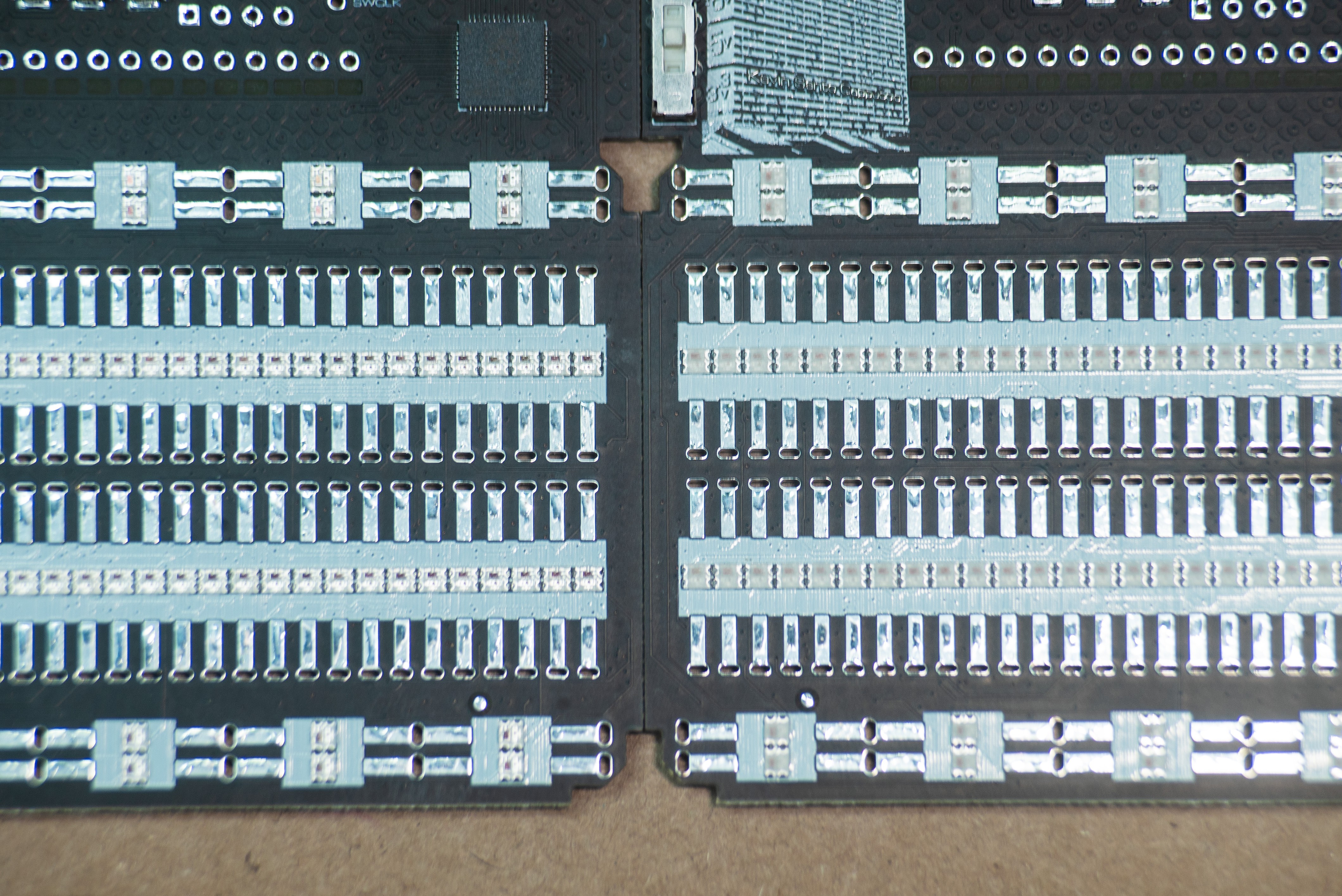

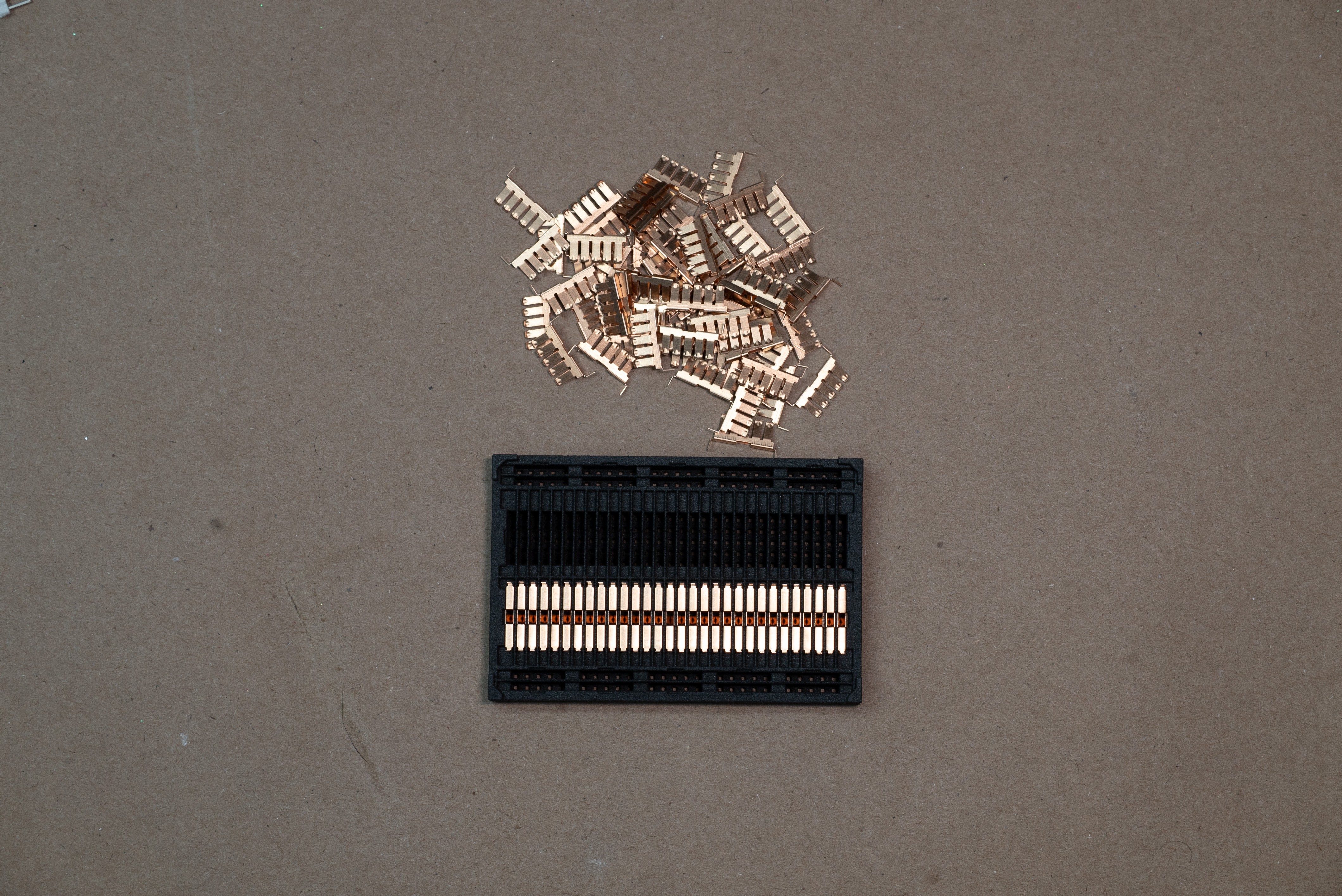

- Put the spring clips into the breadboard shell first and make sure they're all pushed all the way in. Then gently put that onto the main PCB, it may take some careful wiggling to coax all the tabs on the spring clips to go into their holes. If you can't get it seated, take it off and check that they're all straight and in a nice row. If some are giving you trouble, bend it back or swap it out (I have included extras.)

![]()

![]()

![]()

![]()

![]()

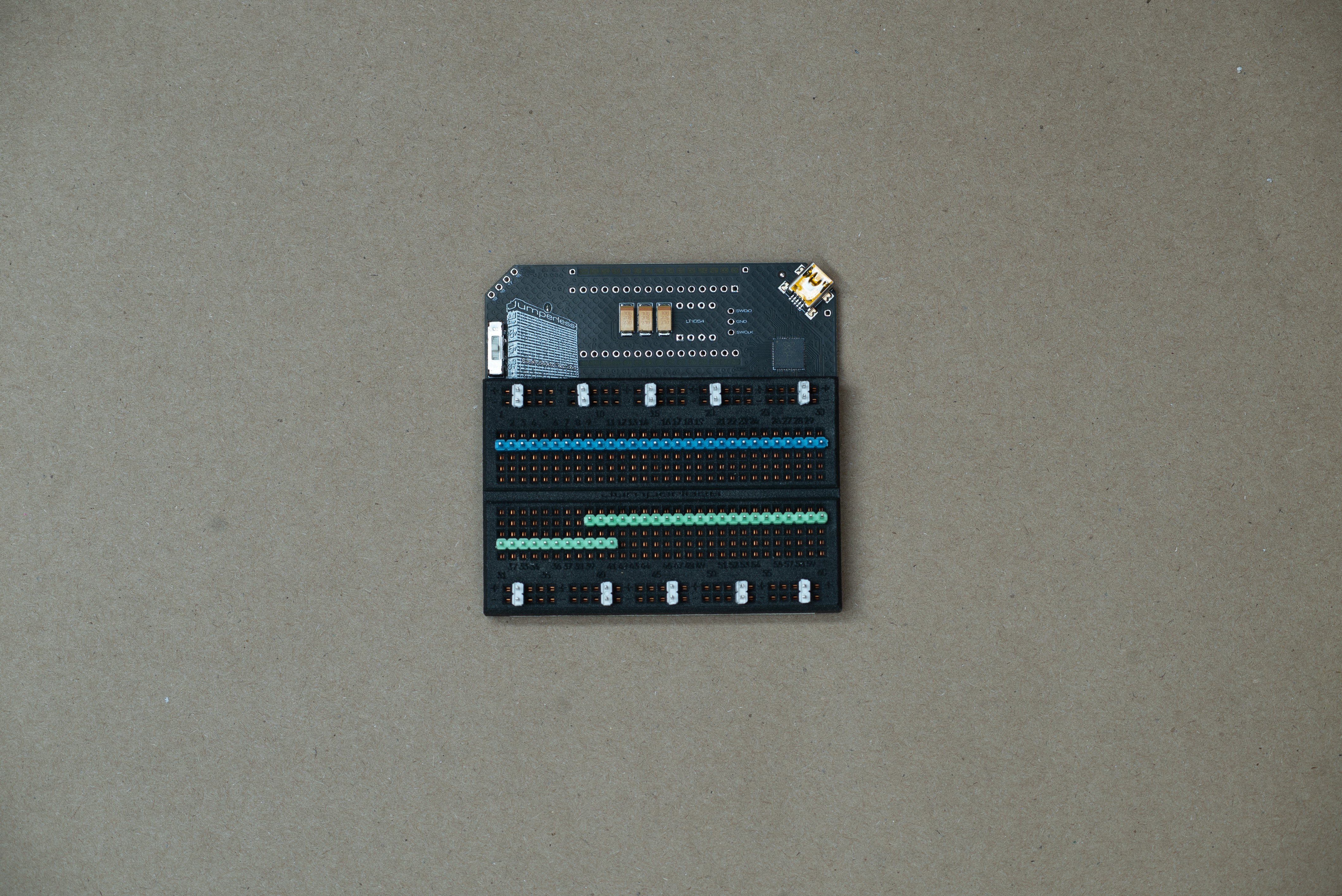

- Stick pin headers into every row of the breadboard and leave them in for soldering. Put them in one hole from the center hole. This makes sure that all the clips are perfectly aligned.

![]()

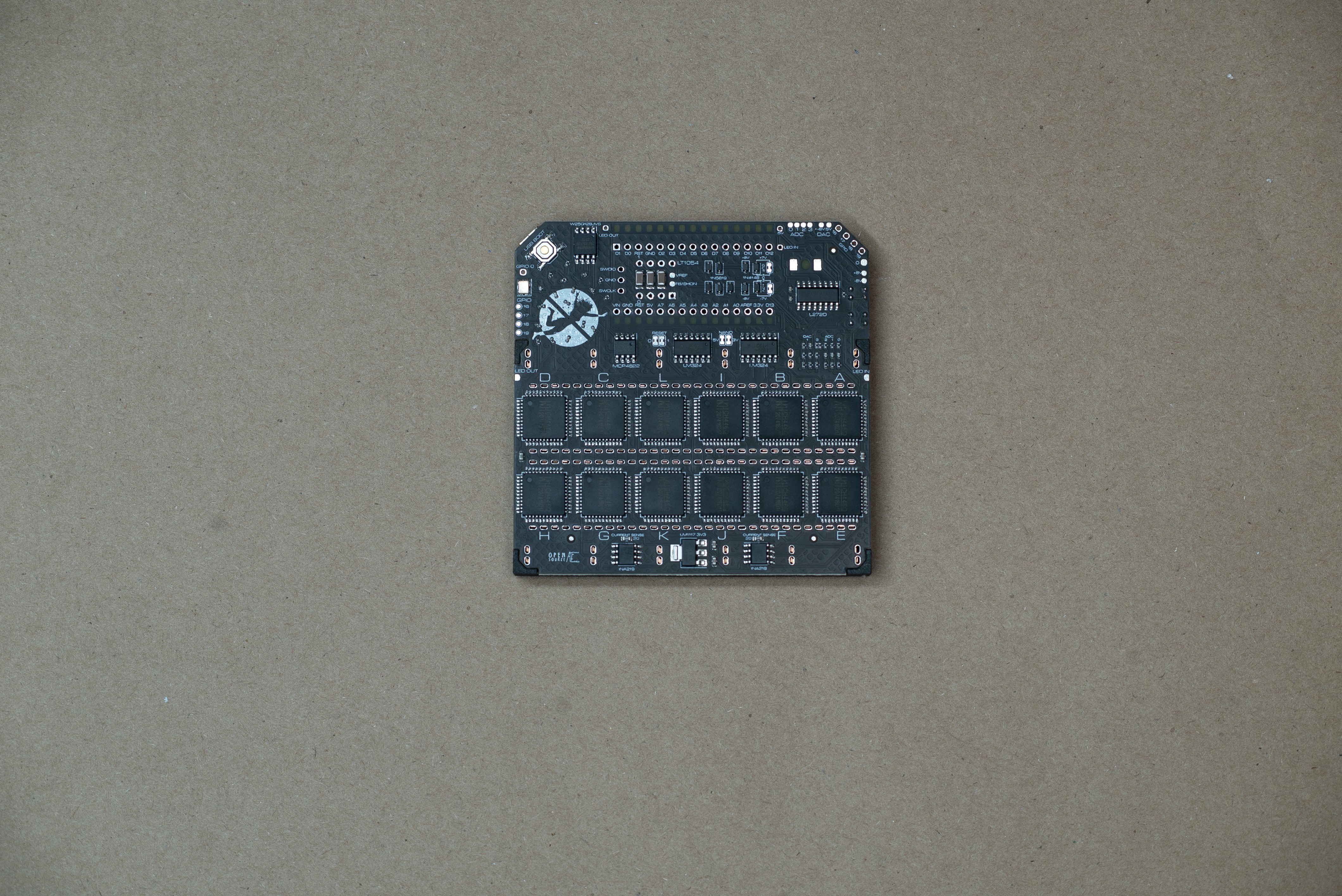

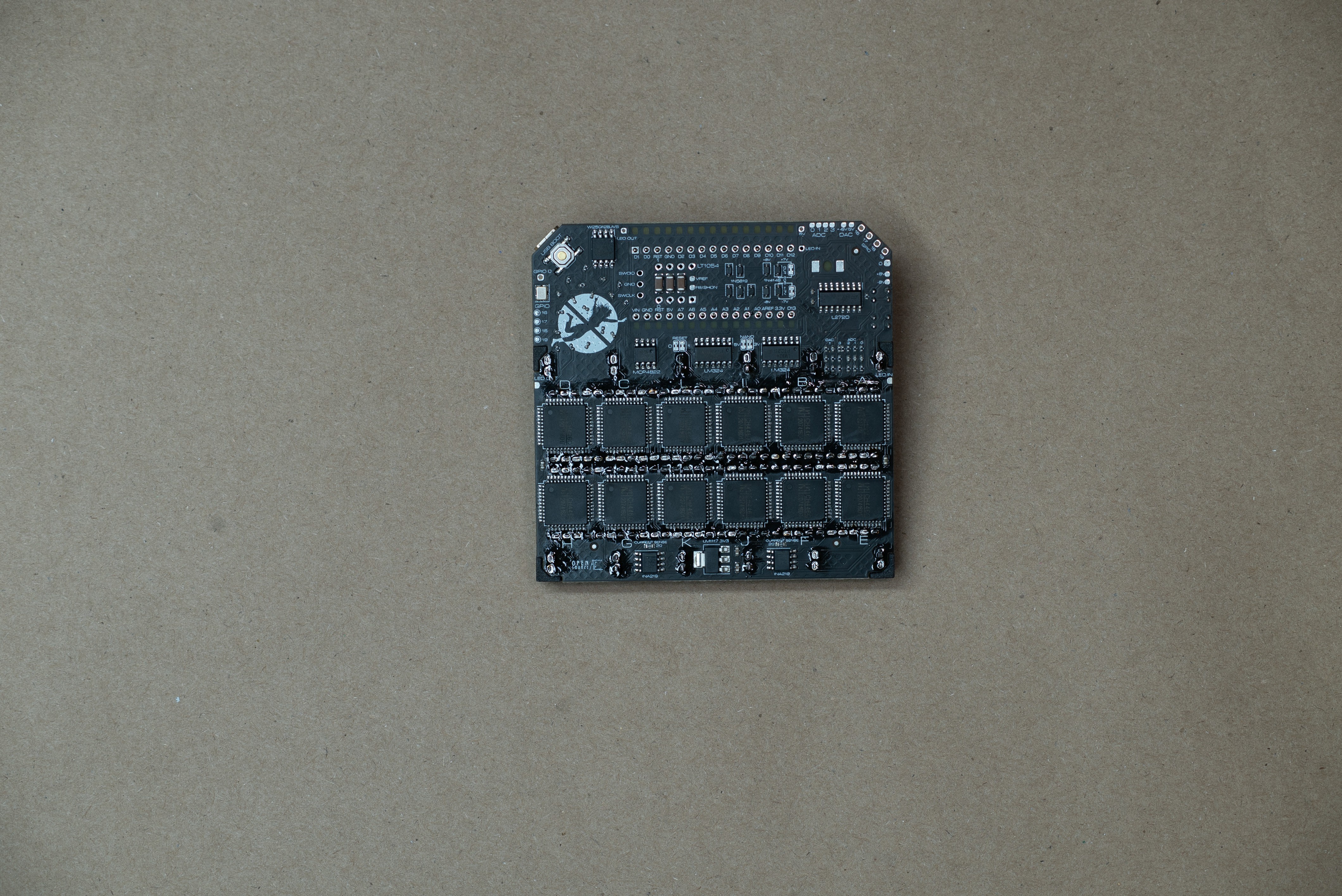

- Solder all the clips, it works best to use a large soldering iron tip and start from the middle on each row. The breadboard will expand slightly as it gets warm so I try to account for that by making sure it expands evenly from the center.

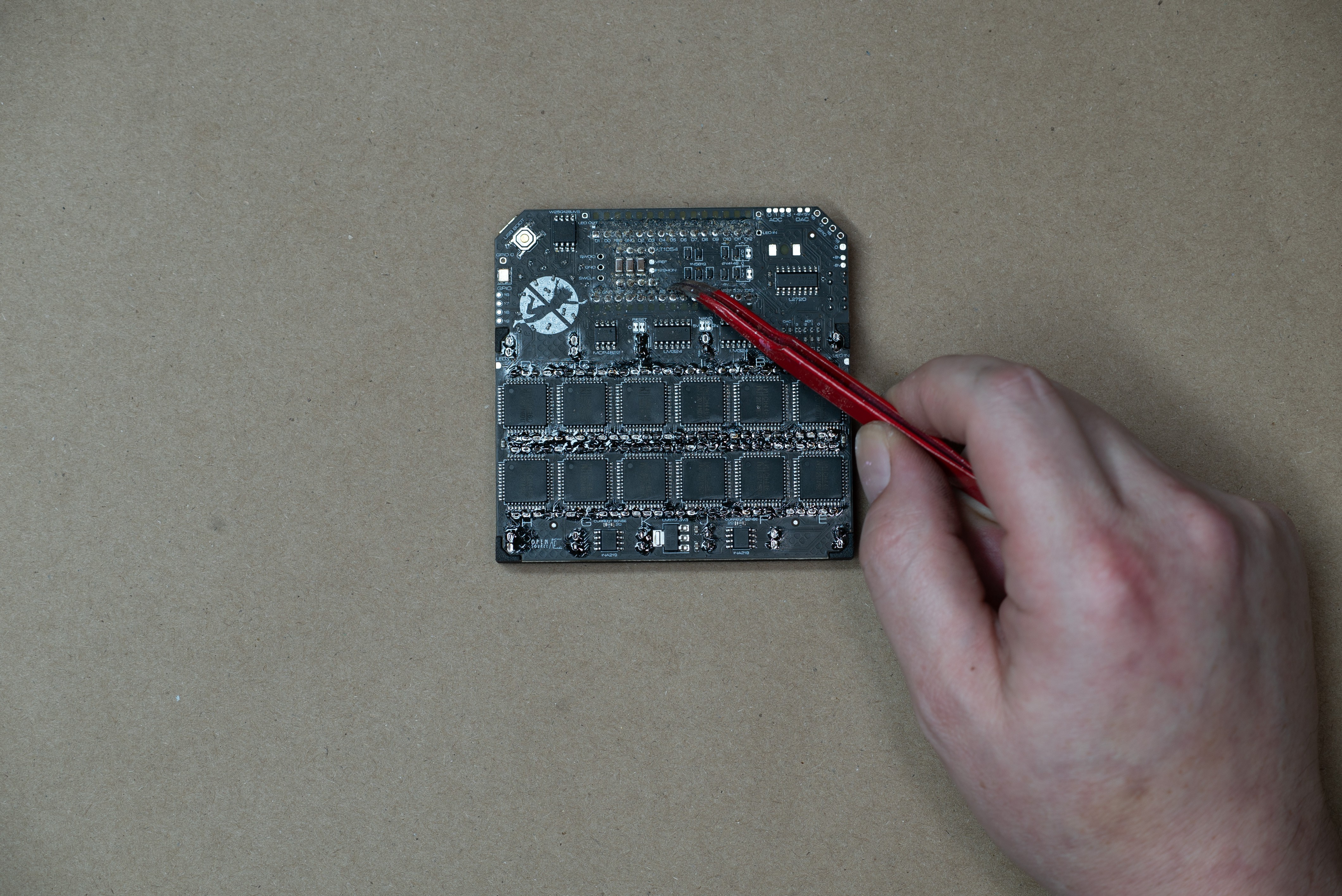

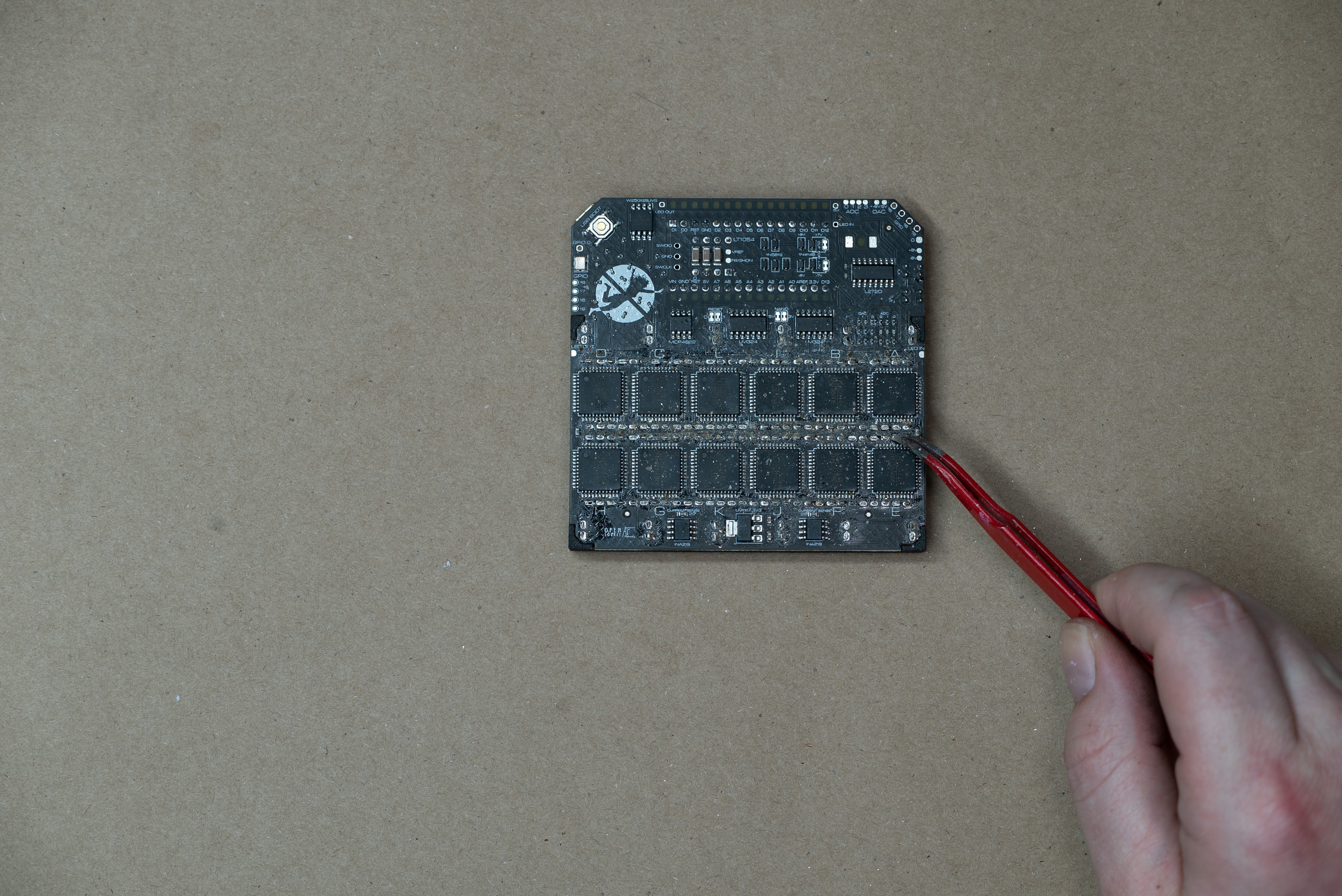

- Be careful not to short any of the pins on the CH446Qs, if you do, use some desoldering braid to get it off. It's a good idea to double check this because it can cause some really confusing behavior (ask me how I know, it was actually the exact board you see here because I was trying to solder without getting my head in the shot).

![]()

- Place the LT1054 into the footprint between the headers, on the front side of the board. Pin 1 is the bottom left (the square pad) so the notch on the chip should be towards the big yellow capacitors.

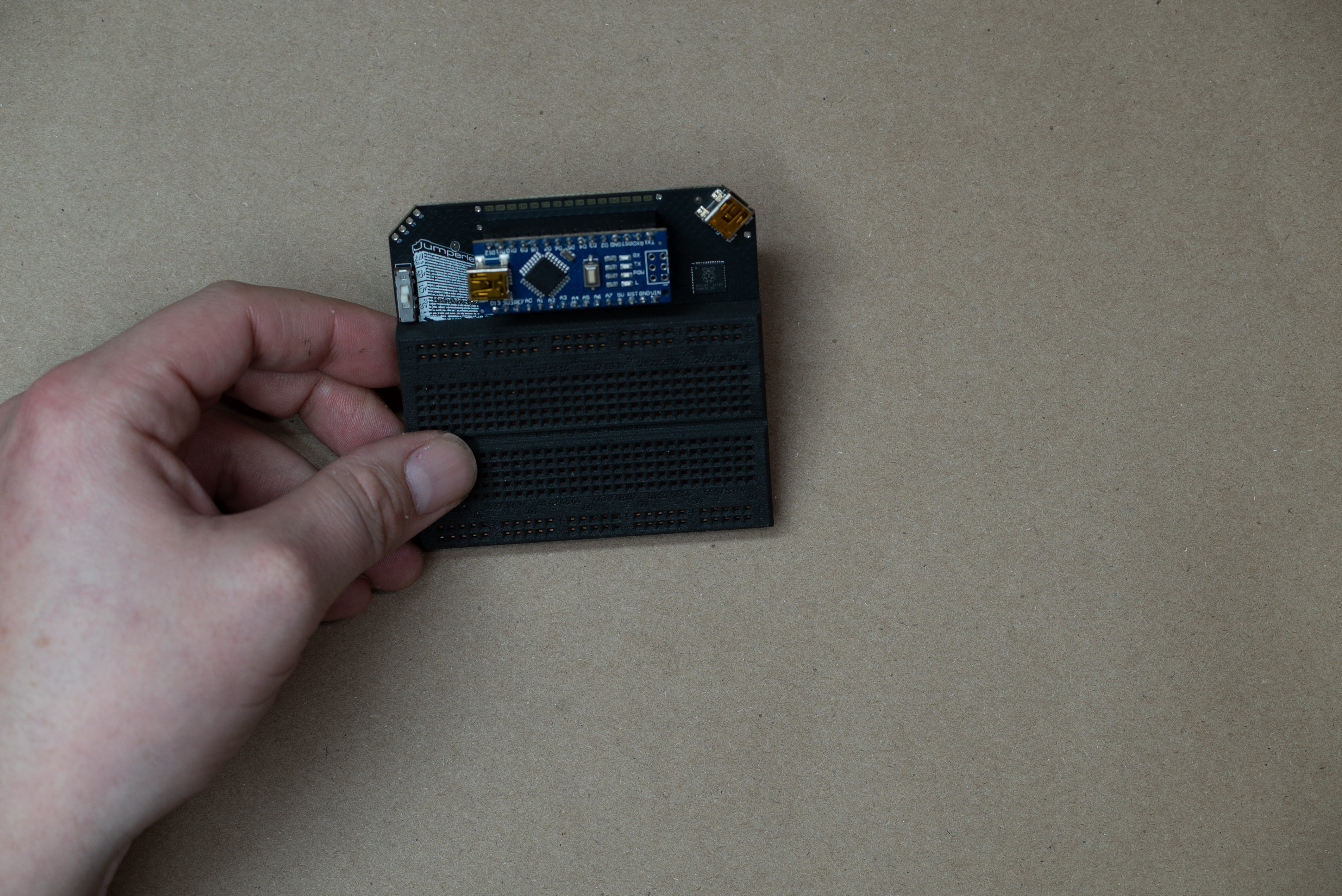

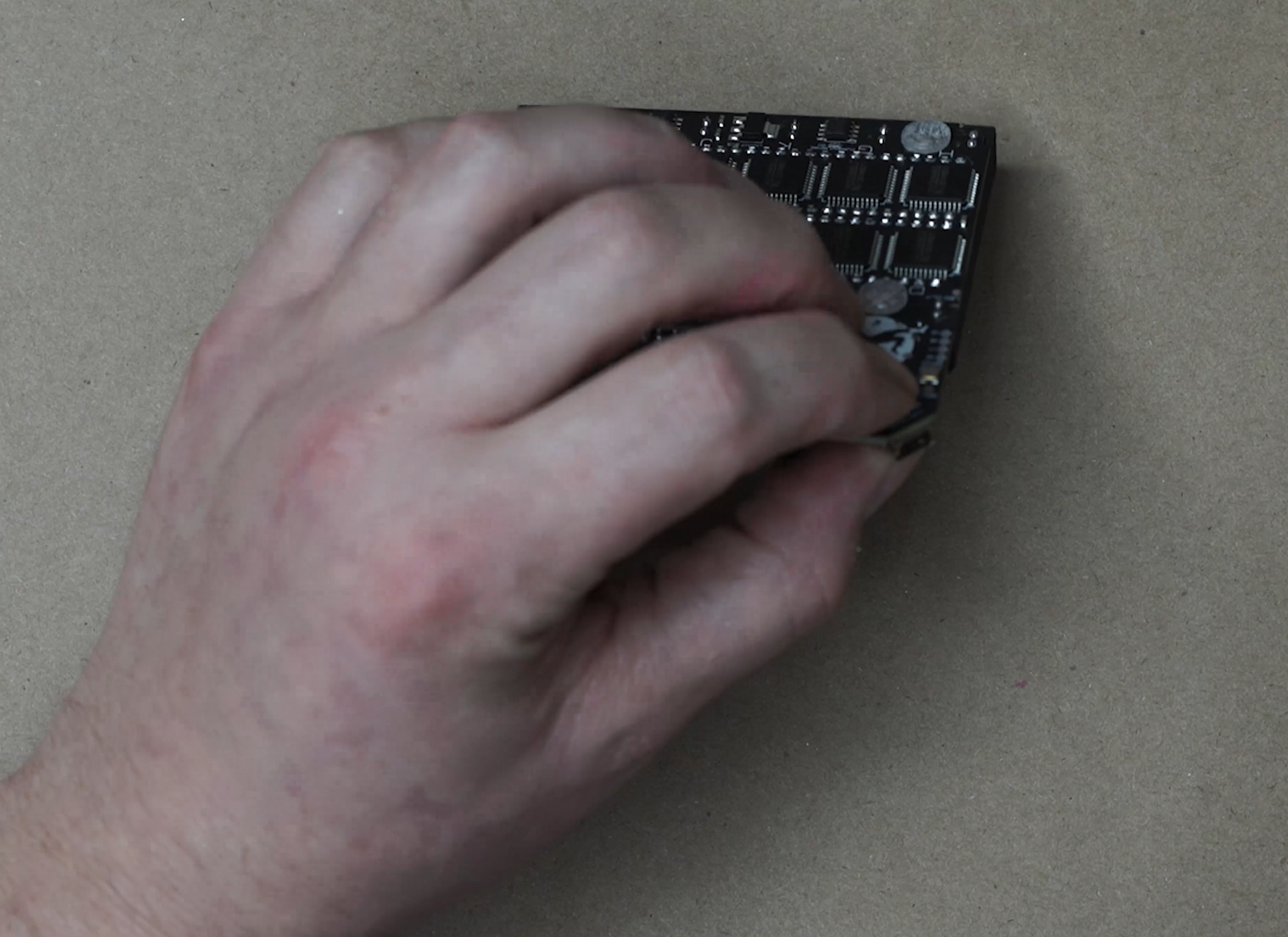

- Stick an Arduino Nano in the top headers while you solder them so they stay straight, before doing anything with the wishbone LED board. And wiggle it around to find the nicest looking position (the holes are slightly bigger than the pins so you can wiggle it ~0.5mm) if you're a total perfectionist like me. Then solder it in.

![]()

![]()

![]()

![]()

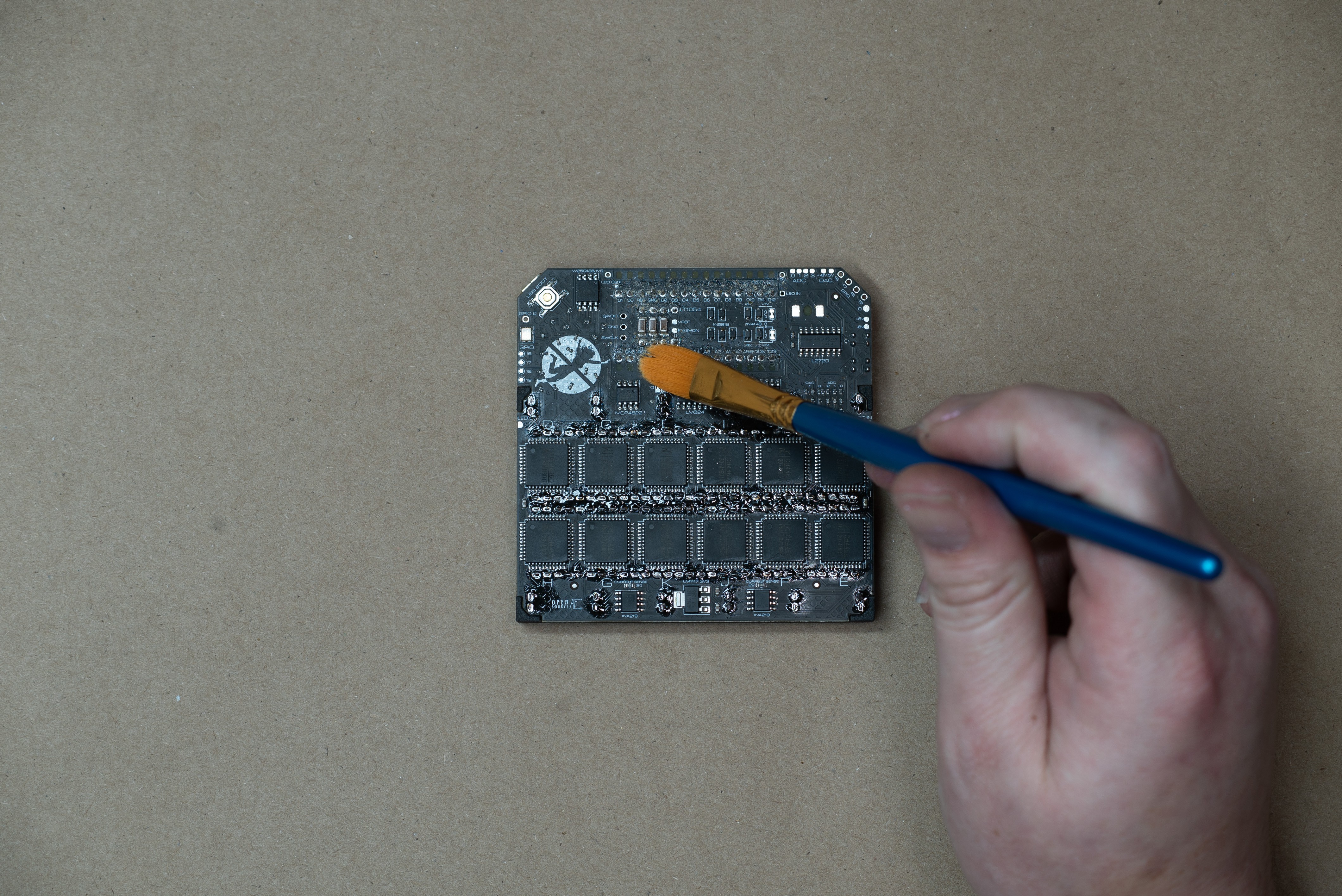

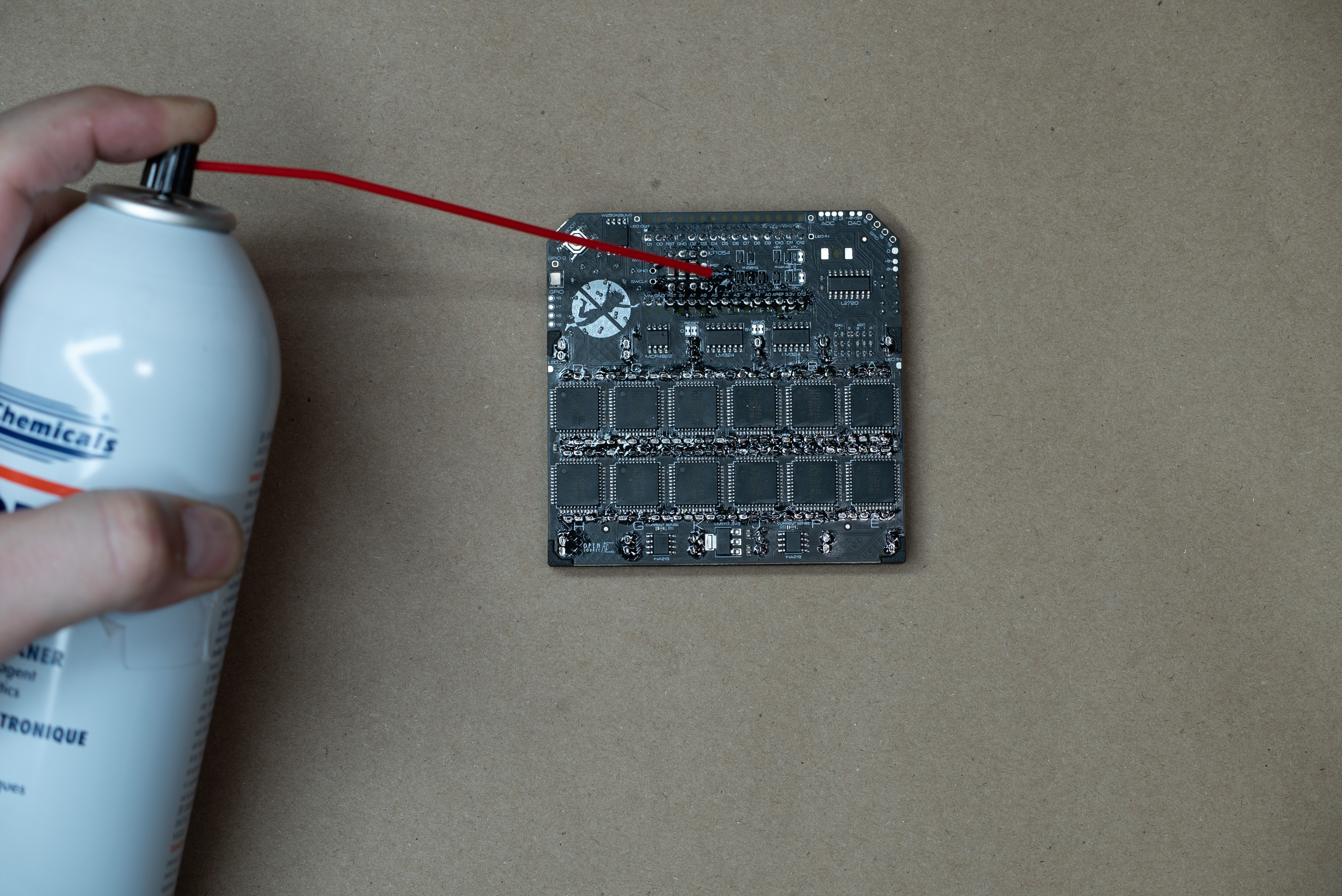

- You'll want to clean off the flux before you put on the wishbone board so there isn't any flux between the LEDs and the PCB. I like to shatter it all by dragging pokey tweezers over it, brush it off, and then use alcohol swabs or MG Chemicals Super Wash spray (this stuff is an absolute game changer, I recommend getting a can)

![]()

![]()

![]()

- For the wishbone board, solder the 2 inner ground pins directly to the backside of the female header pins that are sticking through. Make sure the LEDs lay flat to the main board.

![]()

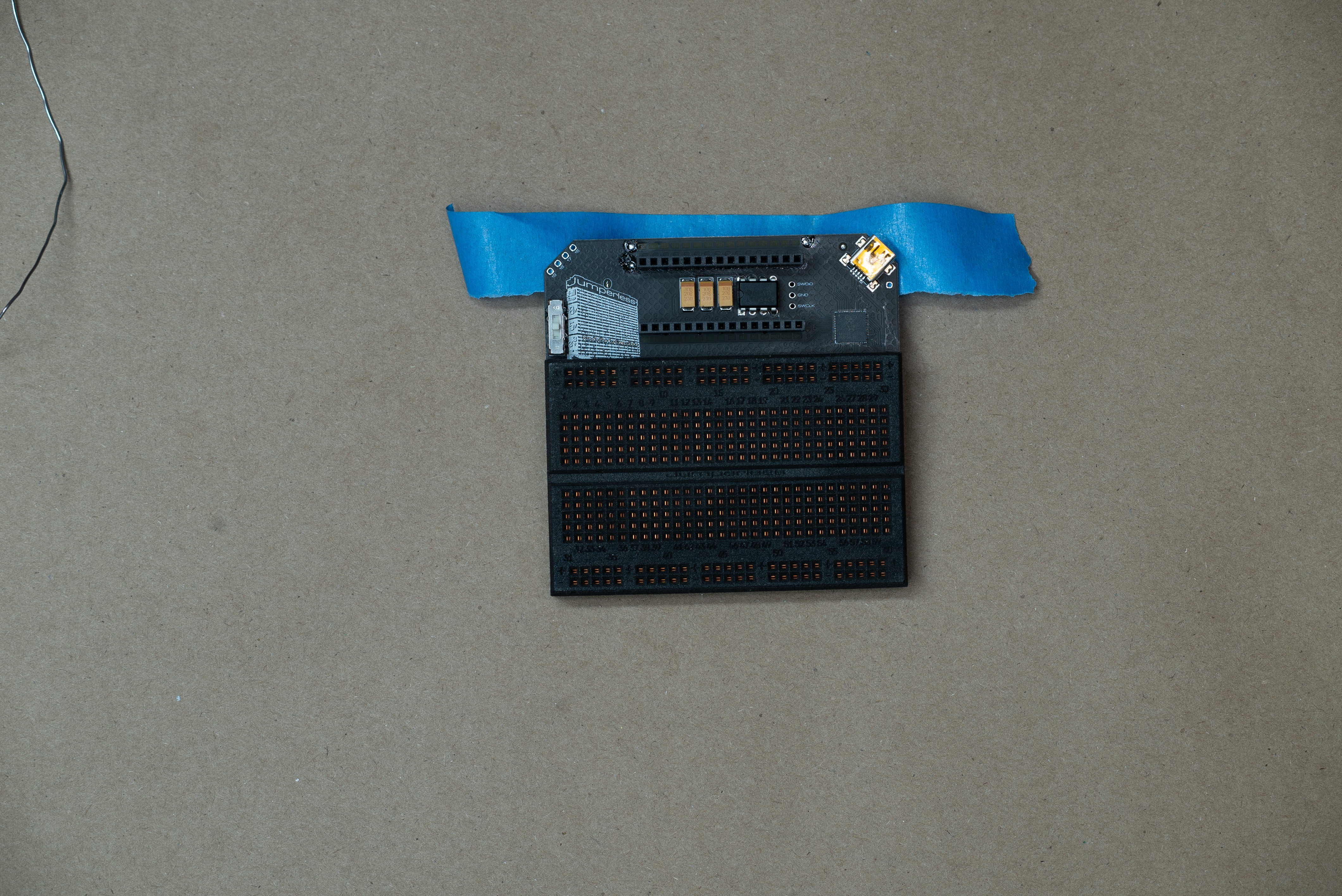

- Stick the 3 other header pins through the wishbone board just far enough that they're flush on the top of the main board. If you stick the short side of the header pin up to the plastic, it turns out that is the perfect length. Tape the headers down so they don't fall out when you flip the board. Solder from the front of the main board first so it's just a flat spot of solder. Now cut the header pins flush before soldering. None of this is strictly necessary, but it leaves the board looking really nice instead of having soldered-then-cut poky headers.

![]()

![]()

![]()

![]()

- Clean off all the flux like you did above.

![]()

- Peel and stick the rubber feet, 2 on the bottom, 1 by the GPIO headers, and 1 just under the logo on the back. If it's a bit wobbly, a small amount of heat will soften the one giving you issues, then press it onto a flat surface until the wobbliness is gone.

![]()

![]()

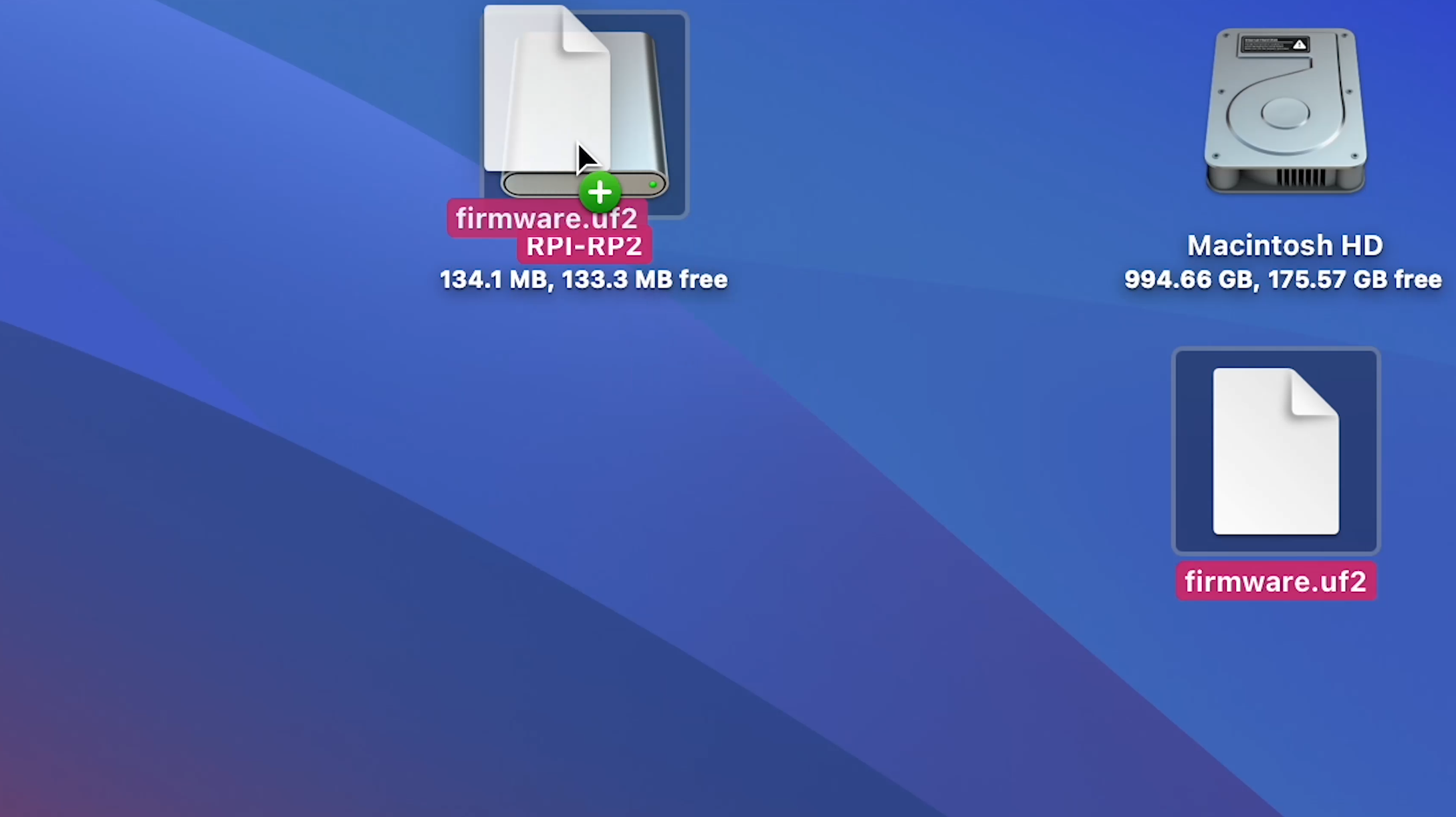

- You can load the firmware by plugging it in with the USB Boot button held and dragging the .uf2 file from here into the drive that pops up as RPI-RP2

![]()

![]()

![]()

And your Jumperless should be good to go!

![]()

Kevin Santo Cappuccio

Kevin Santo Cappuccio

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.